Interroll, one of the leading specialists within the field of materials handling, logistics and automation will be exhibiting a range of products at IMHX 2013 that are deployed on a global scale – wherever goods have to be conveyed, stored or distributed.

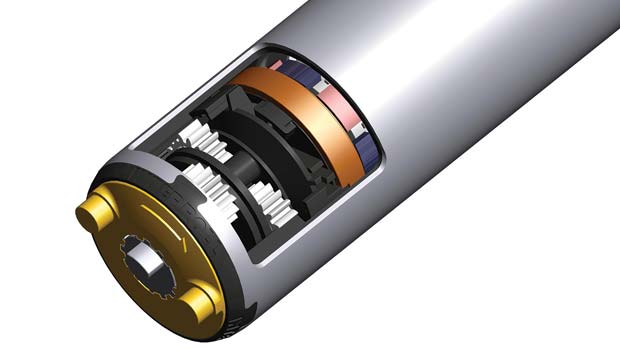

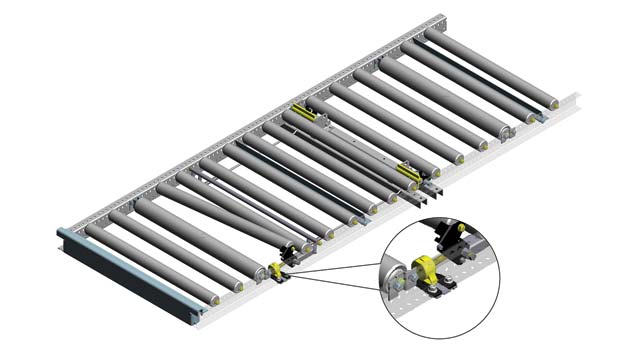

These will include details of easy-to-integrate drive solutions such as drum motors for belt conveyors, DC-powered and non-powered rollers for conveyor systems, through to user-friendly conveyor modules, state of the art cross belt sorters and its comprehensive range of dynamic storage solutions for pallet live and carton live buffer and order picking.

Dynamic energy-efficient flow storage roller and wheel modules are compatible with racking systems worldwide and provide ideal picking solutions, optimising on available space and offers maximum flexibility and efficiencies to store fast turnover stock, with accurate FIFO or LIFO flow of products. These decisive advantages offer many tangible benefits that result in a quick return on investments.

Interroll dynamic storage can be integrated and interfaced with conveyors, automatic stacker cranes and paperless “Pick to Light” system.

New Pallet Flow Speed Controller & Time Delay Safety Separator

Interroll exhibits for the first time at IMHX its new wearless speed controller designed to provide safety, reliability and a high life expectancy. Aimed specifically for logistic operations with high throughputs, the new Interroll speed controller is capable of controlling up to 90 pallets/hour compared to 30 pallets/hour with comparable speed controllers. This key element prevents an uncontrolled pallet flow and in case of damage to the speed controller it will automatically lock down to stop the pallet.

The travel speed of pallets in the gravity driven lanes is an important safety factor and the Interroll speed controller limits the speed independently from the weight of the pallets, 25kg to 1400kg in the same lane, to less than 0.3m/sec. The controlled speed maintains the stability of the load and avoids pallet impacts.

The new Interroll PF 1000 Time Delay Safety Separator makes FIFO pallet flow easier enabling pallets of different sizes and weights to be stored in the same flow channel.

The safety separator keeps the first pallet at the unloading face separate from the other loaded pallets and their accumulation pressure. This way, forklift drivers have 20 seconds to extract the pallets safely before the next pallet moves into position for unloading.

The function, quality and reliability of the new separator were thoroughly tested at the Interroll Centre of Excellence in La Roche sur Yon, France at ambient temperatures and in the in-house freezer rooms down to -28°C. Flow storage has undergone continuous developments and independent documented information comparing flow store technology with conventional static racking can be viewed by downloading this brochure online. – DOWNLOAD IT HERE

Versi Flow – Optimise Your Picking Process

Also to be displayed, is a versatile modular wheel system – Versi Flow, supplied in pre-assembled modules, which can quickly and economically be fitted into racking to create dynamic, versatile carton flow storage.

The densely packed, complete modules provide for ultimate flexibility as changing carton sizes can be accommodated without the need for track and guide re-configuration. Interroll Versi Flow allows you to achieve 90% space utilisation and efficient storage on a first-in first-out principle (FIFO) and can be used for storage of many FMCG including food and grocery goods, wines and spirits, freezer stores, stationery, books and other fast moving items that may also be date sensitive.

For further information visit IMHX 2013 stand no: 20F102 or the website www.interroll.com

For further information visit IMHX 2013 stand no: 20F102 or the website www.interroll.com

Interroll Ltd

Tel: 01536 748 565

Email: B.Urban@interroll.com

Comments are closed.