The Newland Auto-Loader has been a standard model in the Newland range of vehicle loading/unloading conveyors since its conception & manufacture in 1990 when fifteen units were supplied to Freemans in Peterborough.

Since then we have supplied Auto-Loaders to various companies in the UK and worldwide for loading ‘catalogue sacks’ & mail bags, including QVC.

Newland were first approached in 2007 by QVC regarding the automatic loading of cartons into trailers.

Newland initially were a little cautious as the Auto-Loader is a well-established & proven design for loading mail sacks & catalogue bags but had never been used for loading cartons/boxes.

Mail sacks & catalogue sacks have a natural ‘angle of repose’ when loaded on top of one another whereas cartons / boxes behave totally different. Especially as the cartons at QVC are of varying size & weight.

Trials were carried out at the QVC distribution centre in Knowsley using one of the Newland multi-telescopic units from the hire fleet. Fitted with sensors & mounted on a mobile twin powered chassis to simulate an Auto-loader telescopic unit with slewing left/right & raise/lower movement.

Working closely with John Pickavance Engineering Maintenance & Project Manager of QVC & his engineering team, trials were carried out over a four month period.

The trials proved to be very successful, going through a number of Auto-Fill cycle patterns and using all the different carton sizes & weights. From the information gathered, a program using Siemens software was designed specifically for the loading of cartons/boxes to avoid any damage & give a minimum of 80% trailer fill.

QVC have recently installed a fourth Auto-Loader. The Auto-Fill program has evolved from the first machine installed at QVC to the current ‘Waterfall Effect’ vehicle fill pattern.

The Auto-Fill cycle starts with a low level left/right sweep of the vehicle building up to the ‘Waterfall’. Sensors mounted on the front telescopic boom in a specially designed pvc casing detect product build-back, vehicle walls & ceiling.

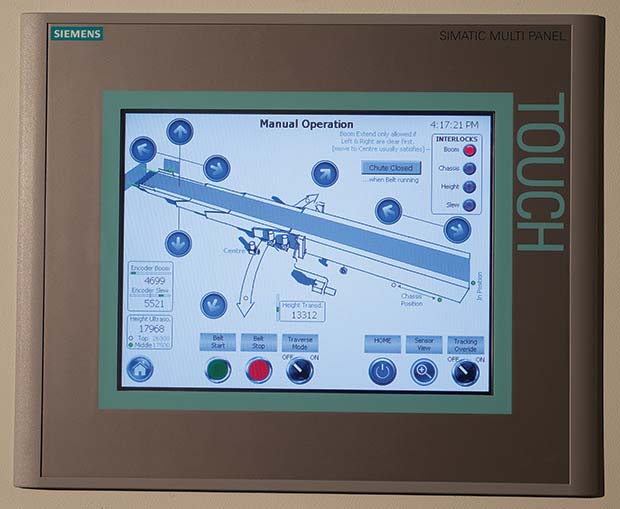

The control panel panel is fitted with a HMI touch screen showing graphic’s with:

• ‘Real Time’ Vehicle Fill.

• Auto-Fill Cycle Complete

• Machine Diagnostic fault check of motors & sensors

The HMI screen can also include machine maintenance schedule & manual

When the Auto-Loader has completed its fill cycle it automatically fully retracts & lowers to its ‘At Rest’ position. Giving an output signal at the same to a flashing beacon from the control panel to indicate fill-cycle complete.

The Auto-Loader is mounted on a powered slewing chassis to move in an arc left/right & right/left.

The QVC Auto-Loaders are also fitted on two additional chassis. Traversing chassis to enable the Auto-loader to operate on several doorways and a forward /reverse chassis.

John Pickavance commented: “We are extremely pleased with the performance of the Auto-Loaders. Cartons are received onto the Auto-Loader belt from a tilt tray sorter. Initially the project was contracted for a minimum of 2000 items per trailer, we are now averaging 6500 items.’’

Mrs Lynn Kerfoot MBE Managing Director of Newland Engineering commented: “We worked together with the engineering department of QVC as a team. The relationship & trust between our two companies was very good & ultimately very beneficial to both.

We can now offer true ‘Hands Free’ loading of non palletised cartons to end users & also system intergrators. From high bay storage to vehicle despatch’’.

Video footage of the Auto loaders at QVC can be viewed on the Newland website: www.newland-conveyors.com

Comments are closed.