It is not unfair to suggest that loading bay design has come a long way in a few short years. Where once logistics providers picked their docking equipment from a catalogue list of available options, the project work of ASSA ABLOY Entrance Systems within the distribution sector this year demonstrates that today’s loading solutions are designed, tailored and built around the client. The rise of custom built warehouses, DC’s and hubs is testament to this fact – business owners recognise the need to have facilities that seamlessly integrate into their operation.

Each bay, dock and access point requires an entirely unique mix; health and safety, security, ease of access, type of traffic and insulation are primary, but not exclusive, considerations. The most suitable balance of these needs must be found and applied to every opening, resulting in entirely different solutions being requested and designed for ambient, chilled, cold and frozen chains.

During 2014 alone, ASSA ABLOY Entrance Systems completed work on a new ‘process led’ 33 acre Parcel hub for DPD, one of the largest sheds in Europe, featuring 265 Crawford dock levellers and 289 Crawford industrial doors. The specialist demands placed upon a parcel distribution facility required customised doors and docking equipment to guarantee the efficiency of the operation, specifically with regards to servicing vehicles from raised docks and at level access openings. The flexibility of Crawford equipment was cited as a key factor in the awarding of the contract.

Also on site in 2014 were the regional distribution centres of Brakes Food Group, whose multi-temperature distribution facility in Glasgow utilises 48 loading bays in ambient and cold storage areas. Brakes property development team worked directly with ASSA ABLOY Entrance Systems project designers to adapt standard loading systems to the challenge. Vehicle bed heights, fleet trailer types and the Brakes Group sustainability targets were key focus areas in design, requiring modifications to standard Crawford docking equipment.

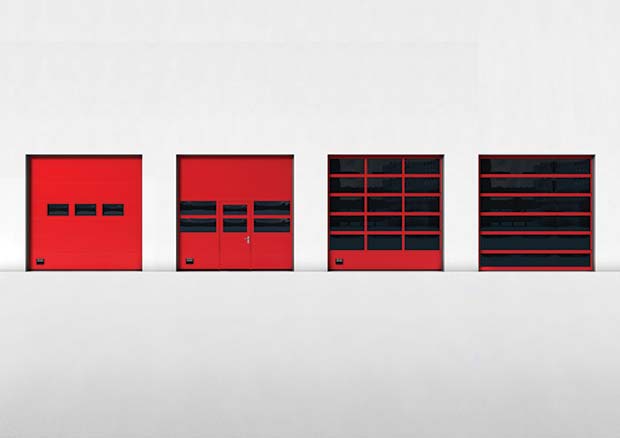

During 2014 a number of enhancements to existing products were released, and brand new entrance products added to the portfolio. These included the release of the Crawford OH1042 overhead sectional door, which is described as “probably the most energy efficient model of its kind” and comes with a host of glazing, colour and security options. Occupiers of ‘speculatively built’ sheds have used the versatility of this door as a means to meet operational requirements specific to their supply chains. Additionally, new ‘Crawford Modernisation Kits’ offer owners of older equipment the opportunity to take advantage of the Crawford OH1042 without extensive building work.

ASSA ABLOY Entrance Systems has also welcomed the Albany range of fabric and rigid high performance doors to the UK, joining the already extensive Crawford high speed door range. Broadening the available options in energy saving high speed doors aligns with market trends, with fast acting doors increasingly popular. Rigid metal doors – which include the energy efficient Albany RR3000ISO with its 40mm insulated panel – and fabric curtain roll doors open at speeds up to 3.2 m/s and can be used in almost any facility. These flexible doors have been accentuated by solutions designed for specific applications and specialised capabilities; machine protection, conveyors, freezers and cleanrooms. Albany products are popular across the globe, particularly within advanced manufacturing plants and pharmaceutical sites.

Loading bay safety continues to be of paramount concern to all within the industry, requiring not only new technology, but also expert maintenance of existing equipment. The ever-present dangers of drive-off and premature vehicle departure have been addressed, with the addition of specialist equipment to the ASSA ABLOY Entrance Systems product range. The Crawford Dock-safe is available for demonstration at the dedicated training centre in Rotherham, South Yorkshire, which holds year-round training courses for pedestrian and industrial door technicians.

The preventive maintenance schedules offered by the ASSA ABLOY Entrance Systems UK service network have helped many fleet operators meet safety legislation. Around the clock repairs were performed throughout the United Kingdom, with RNLI and DPD sites amongst the latest to enlist their planned maintenance schedules. With over 100 engineers covering all of the UK, ASSA ABLOY Entrance Systems is the largest, most comprehensive door service offering to businesses in the UK.

The commitment to developing ever stronger solutions for entrances has been acknowledged by customers, the press and industry bodies. ASSA ABLOY Entrance Systems have secured EPD (environmental product declaration) for a number of products and in August, ASSA ABLOY was again listed in the Forbes “100 most innovative companies in the World,” for the second consecutive year.

Company information

Comments are closed.