The Lenze Smart Motor is a new and unique drive for horizontal and vertical material handling. It is a combination of a standard IEC frame AC motor with electronics that allows any speed to be set in a range from 500 to 2600 r/min. Setting is by Android smartphone using NFC (Near Field Communication) which is contactless and can be done even without power. But more remarkable is the starting performance. No less than 400% rated torque combined with an adjustable soft start ramp is available to accelerate loads that are both heavy and sensitive.

The high starting torque is achieved by an exact match between the drive electronics and the motor. Typically for a pallet conveyor this can allow the use of an 80 frame motor instead of 90 frame. Once up to speed the smaller motor will run nearer to its rating and therefore with higher efficiency, saving energy. As all the electronics are combined with the motor and nothing is needed in the panel, cabling is easier, faster and lower cost. The cost of shielded cables is avoided and connections can be made by spur or loop from a power bus.

The Lenze Smart Motor can be started and stopped using digital inputs. It is also possible to switch between different speeds, for example run and creep, and different directions. Reversing contactors are no longer required. Furthermore motor protection is integrated for monitoring temperature, short-circuit, earth and phase faults.

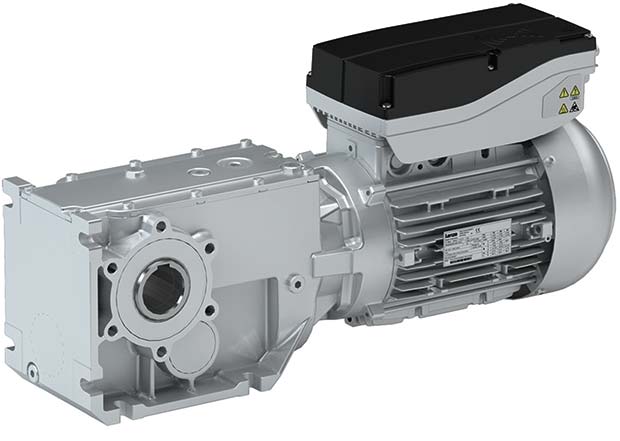

The Lenze Smart Motor is available with helical, shaft-mounted helical and bevel gearboxes for rated output torques from 4 to 650Nm. These gearboxes are from the new Lenze g500 family that combines a broad range of options with compact dimensions. Standard motor options include spring applied holding brakes, blowers and surface coatings for arduous environments. Full catalogue information is available on www.lenze.com, and deliveries can be made swiftly from the range of ex-stock components.

Comments are closed.