- SKU growth and shrinking delivery windows are pushing manual palletizing past its limits

- AI-driven palletizing unlocks speed, accuracy, and ROI without costly sequencing systems

- Early adopters will capture efficiency, safety, and resilience as automation adoption accelerates

As product assortments grow and delivery windows shrink, mixed-case palletizing—the task of stacking multiple SKUs of varying shapes and weights onto a single pallet—has emerged as one of the most critical bottlenecks in modern distribution. SKU counts are rising 18% year over year and e-commerce orders are climbing 15% annually, yet manual palletizing remains capped at 70–300 cases per hour with 1–3% error rates. Labor already consumes 50–70% of warehouse operating costs and injury rates remain among the highest in the industrial sector.

As product assortments grow and delivery windows shrink, mixed-case palletizing—the task of stacking multiple SKUs of varying shapes and weights onto a single pallet—has emerged as one of the most critical bottlenecks in modern distribution. SKU counts are rising 18% year over year and e-commerce orders are climbing 15% annually, yet manual palletizing remains capped at 70–300 cases per hour with 1–3% error rates. Labor already consumes 50–70% of warehouse operating costs and injury rates remain among the highest in the industrial sector.

Jacobi Robotics has released a new white paper, “Mixed-Case Palletizing: Why Now is the Right Time to Automate,” that explores how warehouses can overcome these constraints. The report explains why legacy automation—dependent on costly, rigid sequenced material flow—has been out of reach for many operators, and how new advances in AI are changing the equation.

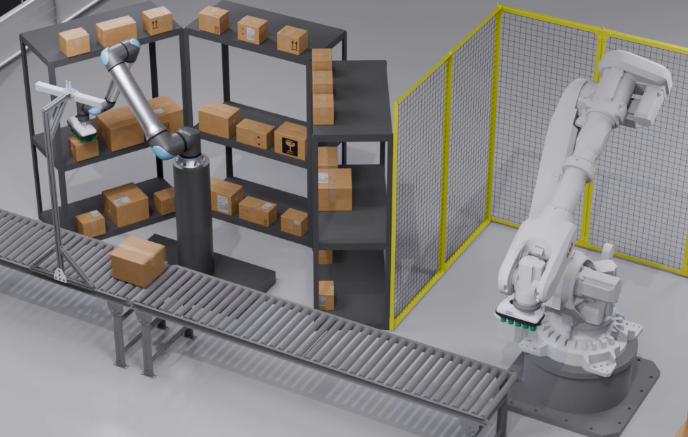

Jacobi’s random, AI-driven palletizer adapts in real time to unpredictable SKU mixes and order flows. By combining 3D perception with advanced motion planning, the system makes stacking decisions on the fly, building stable, dense pallets without sequencing hardware. The result is a 90% reduction in labor and errors, 99% uptime, and a payback period of 6–36 months. Compared with sequenced systems, it lowers capital requirements by 30–50% and fits into existing layouts without major retrofits.

The white paper also outlines a five-step roadmap for adoption, beginning with a data-driven baseline assessment, followed by digital twin simulation, a transparent financial case, and a pilot deployment designed for rapid scaling. This evidence-based approach reduces risk and accelerates ROI, enabling operators to move quickly from pilot to network-wide deployment.

Industry analysts forecast that 80% of distribution centers will implement automation by 2028. With labor costs rising, regulators tightening manual-handling rules, and AI systems reaching maturity, the economics of automation are now undeniable. Early adopters will gain not only cost savings but also resilience, safety, and long-term competitive advantage.

About Jacobi Robotics

Jacobi Robotics is a leading artificial intelligence (AI) and robotics company in Berkeley, CA. Specializing in software for industrial robot automation, the company is redefining automation for warehouses and distribution centers, delivering AI-powered robotic solutions that optimize throughput, reduce costs, and improve operational flexibility. Founded in 2022 by leading roboticists and AI researchers from institutions such as UC Berkeley and Carnegie Mellon University, Jacobi uses proprietary motion planning, simulation, and AI to deliver a first-of-its-kind mixed-case palletizing solution. Proven in production settings, the company delivers complete systems through a network of trusted integration partners, ensuring customers receive proven hardware, expert deployment, and long-term support. For more information, please visit www.jacobirobotics.com.

Jacobi Robotics

Comments are closed.