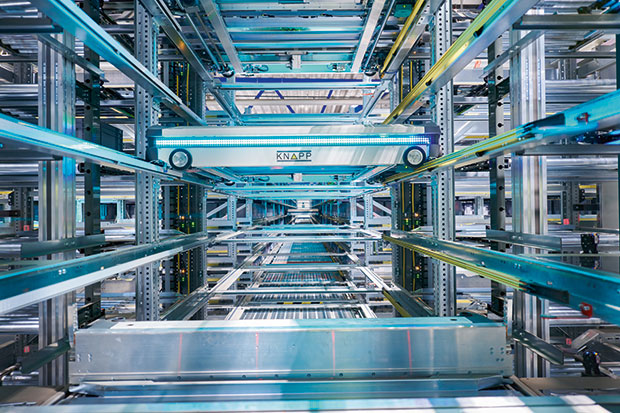

Automation from KNAPP in these enormous facilities has significantly reduced touches in the warehouse, resulting in higher productivity, better service levels and lower operational costs.

With over 10,500 shops and numerous e-commerce websites across 20 countries – plus its growing e-commerce platform, Walmart Marketplace – Walmart’s logistics operations are vast and complex. To address the growing demands of e-commerce and enhance efficiency, Walmart embarked on a transformation of its supply chain, building four next-generation fulfilment centres – known as Next Gen FCs – across the US between 2022 and 2024. The largest has over 200,000 m² of warehousing space, and a fifth is due to come on stream next year. Automation and software from KNAPP have enabled Walmart to streamline a 12-step process into just five steps, boosting productivity and reducing the lead time from order receipt to e-commerce shipping to around 30 minutes.

Right-sized packaging

The solution highlights include KNAPP’s Evo Shuttle 2D automatic store – which combines storage, buffering and sequencing in one system – and the ergonomic, goods-to-person workstations from KNAPP’s Pick-it-Easy Evo series. Another innovation is the right-sized packaging technology, which tailors cardboard shipping cartons to order size precisely, reducing air shipped by around 60% to optimise vehicle space and enhance sustainability. All the automation is controlled by KNAPP’s KiSoft software, which ensures all processes are seamlessly smooth and efficient. Walmart also benefits from KiSoft Analytics, which provides real-time data to derive trends and facilitate forecasts.

Productivity up over 50%

By reducing the 12-step process in the fulfilment centres to a 5-step one, the automation has enabled Walmart to double the number of orders processed each day. “Our productivity has improved by over 50% with the Next Gen FCs,” says David Guggina, EVP Chief eCommerce Officer for Walmart US.

Faster shipping

This productivity increase translates into faster shipping. The four existing Next Gen FCs already cover 75% of the US market with next-day or two-day delivery for millions of items, including Walmart Marketplace products. Together with its traditional fulfilment centres, Walmart now covers 95% of the US with next-day or two-day shipping.

Better product availability

The Next Gen FCs enable storage of up to 10 times the SKUs of a traditional building, allowing Walmart to offer a wider product range, which is especially important during holiday seasons. The automated Evo Shuttle system has doubled storage capacity, enabling enhanced product availability and customer satisfaction.

Greater employee retention

Employees at the Next Gen FCs have better working conditions thanks to the automation. Previously, they were averaging up to 9 miles (14 km) of walking a day but this figure has been drastically reduced. In addition, the ergonomically designed goods-to-person workstations have greatly improved employee satisfaction.

Improved reliability

Efficient, automated processes allow Walmart to deliver the right products at the right time. A team of resident KNAPP Customer Service engineers ensure that the system runs smoothly, with KiSoft CMMS – KNAPP’s smart maintenance management tool – automatically scheduling tasks using data from intelligent sensors.

Lower costs

The automated fulfilment centres are helping Walmart to live up to its price promise to its customers by optimising the use of resources to minimise operational costs. “KNAPP helps us to deliver everyday low costs so that we can deliver everyday low prices for our customers,” concludes David Guggina.

01865 965 000

Stand Number: D96

Comments are closed.