Many of you probably feel the same as me when you think about the future of logistics. Maybe you have fleeting images straight out of science fiction of a futuristic world of AI-driven robots and cyborgs that come when summoned to take care of repetitive, everyday tasks and generally make our lives easier. These visions seem to have inspired the developers of new technology as well, because we’re now witnessing change on a magnitude never before seen. The subject of robotics and human-machine collaboration has been part of the conversation in both manufacturing and intralogistics for several decades now – and has become positively dominant in the past five or six years. This is not just about the stationary robotic arms that handle simple picking, stacking, and sorting. Autonomous mobile robots (AMRs) with high-sensitivity, real-time sensor and machine vision technology are now ushering in a paradigm shift in intralogistical transports, system architectures, and logistics centre design. Growing memory capacities and AI are accelerating computing processes and enabling unimagined depth of analysis, optimisation, and real-time responses in a wide range of applications. And the field of robotics is seeing a fusion of hardware, software, sensor technology, and machine vision to enable process platforms that seemed almost unthinkable a decade ago.

This means that the layouts for efficient material flows in intralogistics, conveyor technologies for intralogistical transports, and gripping and sorting processes in picking and packing are also evolving. The trend toward AMRs, which navigate without any installed infrastructure, continues unabated. The growing acceptance and performance of this technology in the workplace is driving demand and helping AMRs, shuttles, carrybots, and automated guided vehicle (AGVs) gradually evolve into fully autonomous transport devices capable even of retrieving items from boxes.

This means that the layouts for efficient material flows in intralogistics, conveyor technologies for intralogistical transports, and gripping and sorting processes in picking and packing are also evolving. The trend toward AMRs, which navigate without any installed infrastructure, continues unabated. The growing acceptance and performance of this technology in the workplace is driving demand and helping AMRs, shuttles, carrybots, and automated guided vehicle (AGVs) gradually evolve into fully autonomous transport devices capable even of retrieving items from boxes.

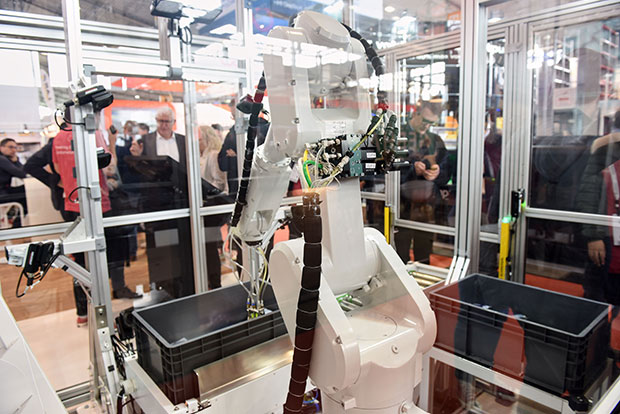

All this will be on full display in the products of robotics companies and mainstream forklift and material handling technology providers at LogiMAT 2024, which returns to the Messe Stuttgart convention centre March 19–21, 2024. Based on compact transport platforms enhanced with robotic components, AMRs are replacing both forklifts and fixed material handling systems in every phase of warehouse processes and in the supply of production and assembly sites.

To reflect the dynamic growth in this segment, AMR and robotics manufacturers will once again have a huge footprint at LogiMAT 2024, filling all 10,500 square metres of Hall 6 as well as selected booths in the gallery of Hall 1. The products on display will include the latest stationary cobots, mobile picking robots, cobots with AI-powered machine vision, and the first fully autonomous AGVs for both indoor and outdoor applications. AGVs can also be found at the booths of many other exhibitors in other halls. Finally, AGV applications will also be featured in the accompanying programme taking place in the LogiMAT Arena, East Entrance Atrium, with experts on hand to offer their insights.

The wealth of products and information focusing on innovations in robotics and AMRs make LogiMAT 2024 a must-attend event for anyone who wishes to keep up with the latest developments and forward-looking solutions in the field of intralogistics. We look forward to your visit!

Comments are closed.