From January 2026, MotionTech UK brings together AMH, L.A.C, and Holloway Controls into a single, unified automation business.

This step reflects how our clients already work with us, not as three separate specialists, but as one joined-up team supporting complex warehouse environments from design through to operation.

By formally aligning these capabilities under one organisation, MotionTech UK creates a clearer, more consistent way for customers to plan, deliver, and support automation programmes at scale.

Why This Matters Now

Warehouse automation projects are becoming larger, more interconnected, and more dependent on long-term system performance. Clients are no longer just looking for equipment or software, they need confidence that every part of the system will work together, now and in the future.

Until now, AMH, L.A.C, and Holloway Controls have supported this need by working closely alongside one another. Each business brought depth in its own area, contributing to successful projects across the UK and beyond.

Bringing these teams together removes unnecessary boundaries. It simplifies engagement, shortens decision paths, and ensures accountability sits clearly with one partner, from early concept through to live operation and ongoing support.

One Organisation, Three Core Capabilities

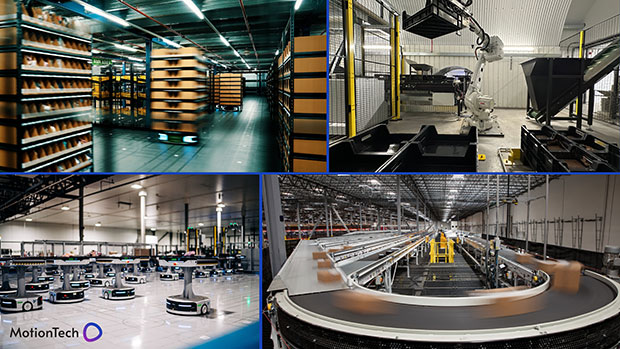

MotionTech UK is structured around three complementary disciplines that reflect how modern automation projects are delivered.

1. Technology Selection Based on Application Fit

Every warehouse operates differently. Throughput profiles, product mix, space constraints, and service expectations vary widely, and technology choices need to reflect that reality.

MotionTech UK supports clients by assessing options across a broad range of automation technologies and suppliers, selecting components based on suitability, performance, and long-term operating cost. This approach helps avoid over-engineering, reduces integration risk, and ensures systems are designed around how a site truly runs.

The outcome is technology that fits the operation, not the other way around.

2. Manufacturing and Build Capability That Matches the Environment

Automation designs only deliver value when they can be built accurately and installed effectively. By combining manufacturing capability within the wider organisation, MotionTech UK maintains closer control over how systems move from concept into reality.

This includes fabrication, assembly, modular system build, bespoke mechanical structures, and custom automation elements, all developed with installation conditions and operational constraints in mind. Whether upgrading an existing site or delivering a new facility, this approach allows systems to be shaped around available space, access limitations, and integration requirements, reducing disruption during installation and commissioning.

3. Controls, Software, and Lifecycle Support

Automation performance depends on more than mechanical equipment. Controls, software, and long-term support determine how reliably a system operates day to day.

MotionTech UK provides controls engineering, software development, commissioning, optimisation, and structured service support as part of the same delivery model. This continuity helps ensure systems are understood, supported, and improved over time, not just handed over and left to run.

Importantly, this capability extends beyond MotionTech-delivered systems. Existing installations, third-party equipment, and legacy controls environments are all supported with the same focus: improving stability, extending service life, and maintaining operational confidence.

A More Joined-Up Experience for Clients

While these disciplines work together as an integrated delivery model, clients can still engage MotionTech UK in the way that best suits their needs, whether that’s full system delivery or targeted support in a specific area.

What changes is clarity:

•A single point of accountability

•Consistent engineering standards

•Fewer handovers between parties

•Better alignment between design, build, and operation

This structure reduces risk during delivery and provides a stronger foundation for long-term system performance.

Looking Ahead

The move to a unified MotionTech UK reflects a natural evolution, one shaped by client needs, project experience, and the realities of modern warehouse automation.

It is not a change in direction, but a clearer expression of how we work today and how we will continue to support customers moving forward.

By bringing proven capabilities together under one organisation, MotionTech UK is focused on delivering automation programmes that are well-considered, well-built, and well-supported now and over their full operational life.

Motiontech UK

t: 0115 9753300

Comments are closed.