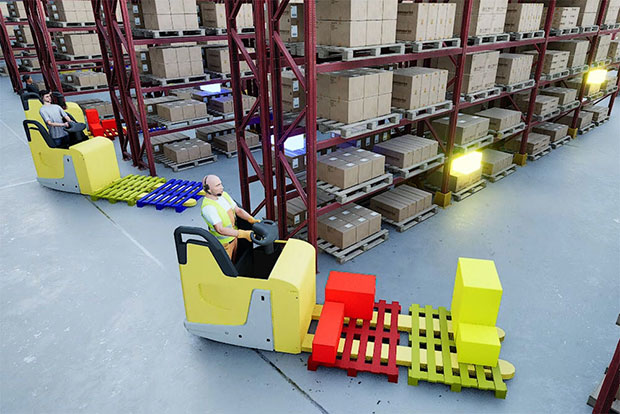

Distribution centre technology provider, Lucas Systems, has announced its new pick-to-pallet technologies, providing an all-new level of optimisation for warehouses picking to multiple pallets and customer locations at the same time.

This exclusive method of ‘best pallet matching’ automatically assigns the optimal two or three pallets to warehouse workers. The capability dramatically boosts productivity by elevating picking efficiency and minimising on-floor travel without sacrificing accuracy.

“It’s inefficient to assign pallets simply because they’re going to the same location or due to other conveniences,” says Andre Lessa, Director of R&D at Lucas Systems. “This is a much more sophisticated way to approach the problem.”

The new solution uses data science to assign work while determining, from among all orders to be picked, which two or three pallets are the best choices for a worker’s picking assignment. The pallet matching system is dynamic, constantly optimising pallet matches as new orders come in with varying priorities.

“This is a sizable improvement from today’s status quo,” says Ken Ramoutar, Lucas Systems CMO. “Today, warehouses might gravitate toward what’s simple to implement, not necessarily what’s most optimal. For example, they might not pick to multiple pallets and multiple stores simultaneously because they believe it will sacrifice accuracy. But this new technology aims to increase accuracy while also adding another layer of optimisation.”

The Lucas Systems pallet matching solution is ideal for high-volume distributors in large warehouses picking two or three pallets at a time. Wholesalers, grocery and food service are among key industries that could meaningfully benefit from the technology.

Associated Wholesale Grocers (AWG), a Lucas Systems customer, is a user of its pallet-matching software. AWG is the nation’s largest cooperative food wholesaler to independently owned supermarkets, serving 1,100 member companies and 3,500 locations throughout 33 states from 9 wholesale division support centres. AWG relies on pallet matching technologies for warehouse efficiency and accuracy of its deliveries.

According to Richard Kearns, EVP of AWG Distribution and Logistics, “As a Member Owned Cooperative, AWG is always seeking new technology to drive efficiency, safety and compliance in our operations. The deployment of Lucas Systems allowed us to do this and more. Due to the diverse sizes of our stores, we were able to group orders together, utilising the pallet matching technology to increase our productivity by reducing our travel path. Lucas Systems also provided benefits in safety and compliance by utilising paperless equipment check in/out procedures. Additionally, the ability to deploy agnostic multi-modal hardware versus proprietary hardware to operate the voice application was a significant benefit.”

Some Lucas Systems customers have reduced travel and increased productivity from 15% to 30% through optimisation. The larger the warehouse, the more the expected gains.

Comments are closed.