Since 2007, Niederrhein-Gold Tersteegen GmbH & Co. KG in Moers, Germany has been relying on automated guided vehicles (AGV) from ek robotics. After the system was expanded in 2019 to include vehicles for transporting industrial pallets, new transport robots were added in 2024, opening further functional areas and ensuring even higher throughputs and efficient material flows with their continuous operation.

With the first expansion stage, a fleet of custom-built vehicles from the CUSTOM MOVE series went into operation. Equipped with two roller conveyors, the vehicles each transport two Euro pallets weighing up to one tonne and supply the filling lines with empty pallets in three shifts. They also transport the finished goods to the pallet wrapper and on to the storage areas. A characteristic feature of the solution is the contactless energy transfer in the floor, which also serves as inductive track guidance – battery operation is therefore not necessary. In 2019, the system was expanded to include additional CUSTOM MOVE vehicles. This expansion also enabled the transport of industrial pallets (1,200 x 1,000 mm) and the automated connection of the high-bay and cold storage warehouses.

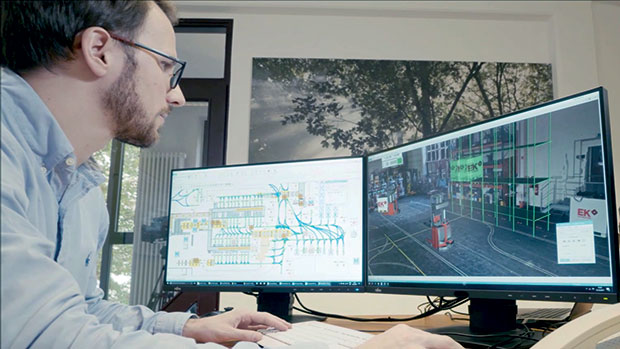

The next expansion stage will follow in 2024: new vehicles will open up additional filling lines and storage areas. The planning was based on detailed material flow simulations, which were used to determine the optimal number of vehicles and future transport volumes. “The simulations provide us with reliable key figures to ensure the performance of the overall system even as requirements increase,” explains Clemens Wollmann, sales engineer at ek robotics. All vehicles are custom-built, designed for high transport performance, short filling intervals, and the specific environmental conditions of beverage production.

Customised transport solutions for the beverage industry

In the international beverage industry, ek robotics primarily uses specially manufactured custom vehicles in addition to series vehicles for projects, including for Arla Foods, Gerolsteiner, and Royal Swinkels Family Brewers (Bavaria). Together, the systems ensure reliable material flows and transport more than one billion litres of beer, juice, and milk annually.

Comments are closed.