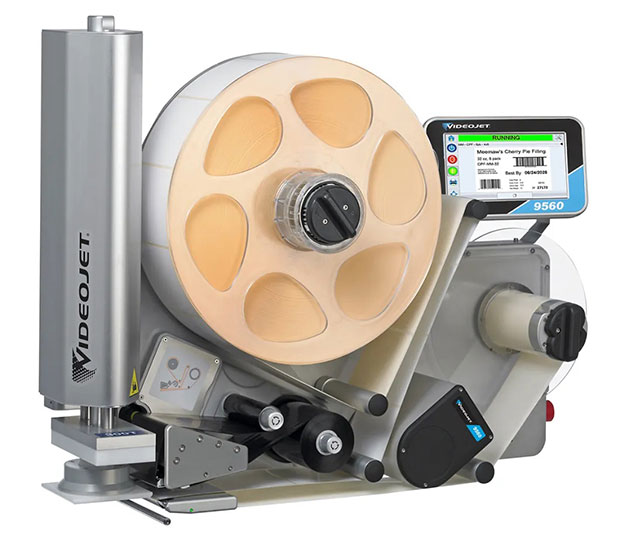

Engineered without the mechanisms that require routine manual adjustments and that may cause label jams in other label print and apply (LPA) systems, the Videojet 9550 has proven to be a dominant solution in the labelling industry over the last ten years. Videojet Technologies, a global leader in coding, marking and printing solutions, has now upgraded this solution with the introduction of the Videojet 9560 print and apply labeller featuring increased processing speeds and expanded connectivity options.

Marcy Vanderbei, Global Business Unit Manager at Videojet, said: “The evolution of the 9550 to the new 9560 with Direct Apply technology benefits end-of-line packaging operations with faster processing speeds and easy integration into existing production and control networks. Each improvement is a testament to our dedication to research and the development of solutions that solve our customers’ coding and labelling challenges.”

Marcy Vanderbei, Global Business Unit Manager at Videojet, said: “The evolution of the 9550 to the new 9560 with Direct Apply technology benefits end-of-line packaging operations with faster processing speeds and easy integration into existing production and control networks. Each improvement is a testament to our dedication to research and the development of solutions that solve our customers’ coding and labelling challenges.”

Direct Apply is a unique on-demand labelling method that allows accurate placement of the label onto the package. The system works by simultaneously printing and applying labels onto the top or side of a passing pack without the need for a tamp or air blast applicator. Achieving speeds up to 150 packs per minute for typical 4” x 6” GS1 barcode labels, the Videojet 9560 maintains throughput, even when packs accumulate.

The Videojet 9560 automated labelling system features the patented Videojet Intelligent Motion™ technology for automatic and precise control of the entire system while targeting zero unscheduled downtime on production lines. This advanced labelling technology improves operating performance with a direct drive that controls label speed and position without clutches, rollers or adjustments. An electronic supply reel automatically adjusts and maintains label tension irrespective of speed and label size from the start to the end of a reel. A simple web path enables label and ribbon changes in less than 60 seconds.

With its fluency in common label design software and printer languages, users switching to the new 9560 will have no need to rebuild job files or retrain. Compared to the 9550, the new 9560 is engineered with increased programmable I/O options for integration with more data protocols including Ethernet/IP™ and PROFINET®.

Comments are closed.