Springpack, a pioneering name in the realm of packaging solutions, is set to make waves at the upcoming Intralogistex event held at the NEC, Stand 310. This exhibition serves as a pivotal platform for Springpack to showcase its cutting-edge sustainable packaging options, alongside an innovative calculation feature that demonstrates potential cost savings for customers through the adoption of their revolutionary Armour Wrap with nano-layer technology.

At Stand 310, attendees can expect to discover an array of Springpack’s commitment to sustainability and innovation. The focal point of their exhibit lies in their sustainable packaging alternatives, exemplified by the highly efficient Armour Wrap and AERO dispenser. This next-generation packaging solution is engineered with nano-layered technology, offering unparalleled strength and durability while significantly reducing environmental impact compared to traditional machine films.

At Stand 310, attendees can expect to discover an array of Springpack’s commitment to sustainability and innovation. The focal point of their exhibit lies in their sustainable packaging alternatives, exemplified by the highly efficient Armour Wrap and AERO dispenser. This next-generation packaging solution is engineered with nano-layered technology, offering unparalleled strength and durability while significantly reducing environmental impact compared to traditional machine films.

One of the standout features of Springpack’s showcase is their unique ability to calculate potential cost savings for customers. By comparing their current machine film with Springpack’s Armour Wrap, attendees can gain valuable insights into the economic benefits of adopting this advanced packaging solution. This calculation tool not only highlights the financial advantages but also underscores the environmental benefits of transitioning to sustainable packaging practices.

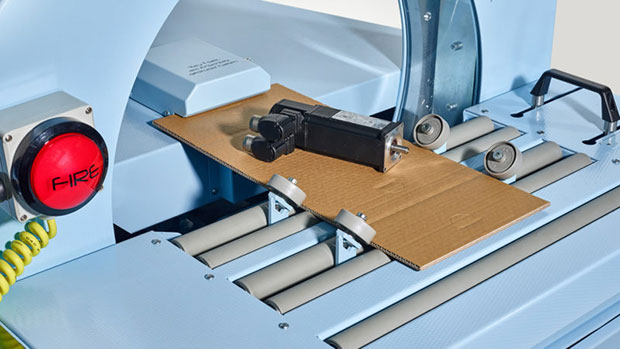

Moreover, Springpack is proud to announce its partnership with Emba-Protec, a renowned manufacturer of packaging machinery. Together, they will introduce the EMBA Buzz n Pack machine at the exhibition. This state-of-the-art packing solution offers a multitude of key benefits that redefine the packaging process:

Packing on Command: The Buzz n Pack machine facilitates up to 4 packaging cycles per minute, ensuring maximum efficiency in the packing operation.

Versatility and Flexibility: With 4 standard sizes covering a wide range of packaging needs, the machine offers unparalleled adaptability. Additionally, it can be adjusted between sizes in seconds, eliminating the need for complex programming.

Consistency and Safety: The machine ensures a consistent packing process, regardless of the operator, thereby enhancing product protection through firm fixation. This not only guarantees product integrity but also minimises the risk of damage during transit.

Reduced Waste and Environmental Impact: By optimizing packaging material usage and offering the option to use recycled film with up to 65% content, the Buzz n Pack machine significantly reduces packaging waste and promotes sustainability.

Efficiency and Ease of Use: Employee training is streamlined, taking only 5 minutes to familiarise operators with the machine’s operation. Moreover, the machine is immediately ready for use without the need for thermal energy, heavy current, or compressed air, offering unparalleled convenience and cost-effectiveness.

Compact Design: The Buzz n Pack machine boasts a small, compact design that fits seamlessly into any workspace, ensuring maximum utilisation of available floor space.

In summary, Springpack’s participation at Intralogistex represents a convergence of innovation, sustainability, and cost-effectiveness in the world of packaging solutions. With a focus on sustainable alternatives like Armour Wrap and groundbreaking partnerships such as with Emba-Protec, Springpack continues to lead the way in revolutionising the packaging industry, offering solutions that not only meet but exceed the evolving needs of modern businesses. Visitors to Stand 310 can expect to be inspired by Springpack’s commitment to excellence and their dedication to shaping a more sustainable future through innovative packaging solutions.

Comments are closed.