Plastic bins and containers can be considered the unsung heroes of modern retail logistics, says Edward Hutchison, Managing Director of BITO Storage Systems.

Performing a vital role inside the warehouse for storage units and as order picking totes, the importance of plastic bins and containers continues outside of the warehouse where they are increasingly used for online deliveries in grocery retail logistics.

Performing a vital role inside the warehouse for storage units and as order picking totes, the importance of plastic bins and containers continues outside of the warehouse where they are increasingly used for online deliveries in grocery retail logistics.

Inside a retail warehouse, plastic containers are ideal for storing a variety of SKUs on racking, shelving or in carton live storage flow lanes. Replacing existing cardboard containers that become tattered and often irregular in size on shelves with resilient plastic bins, not only adds to the protection of goods but also provides a smarter, more uniform look to the work environment. If in live storage, an inclined tail can be placed at the end of a flow lane to tip a bin or container at an angle on the pick face to give staff better access to, and visibility of, what they are picking, thus contributing to pick accuracy. Inclining totes placed on galvanised shelving offers a similar benefit.

Goods picked from storage locations are often put into plastic order totes, which provide a convenient and protective unit to be transported around picking zones, often on a conveyor, as directed by the warehouse management system. When the picking tote is complete, having visited all the required pick zones, it can be sealed and sent to be consolidated into store orders.

Food delivery

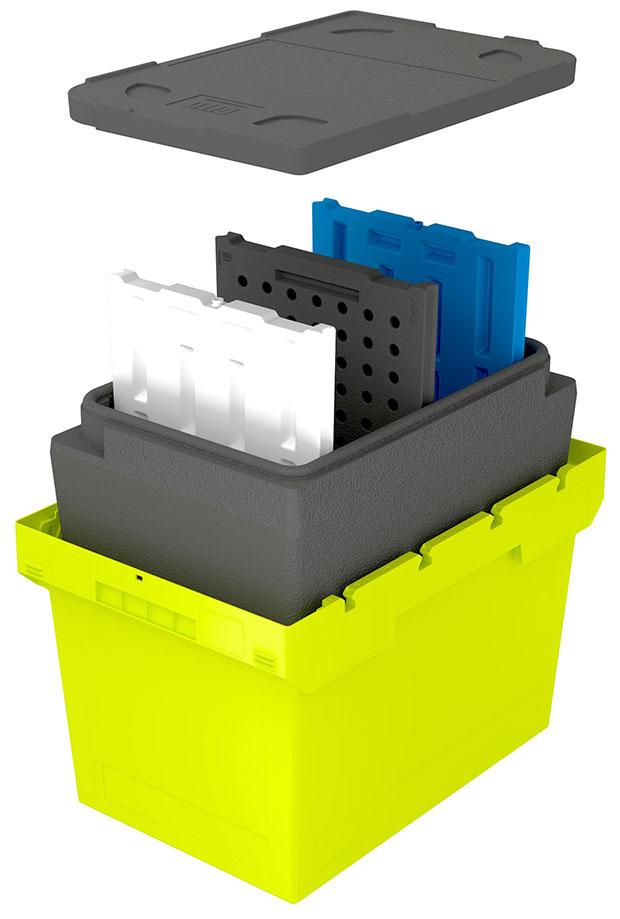

Plastic containers also have an important role in helping online grocery retailers deliver temperature sensitive foods safely to the consumer while minimising packaging waste. In online grocery retail goods must reach the consumer undamaged. Freshness and quality assurance are other top priorities, while compliance with cold chain requirements – from leaving the warehouse to door-step delivery – is essential. In addition, goods that need to be shipped standing upright must be secured against tipping over. Another requirement is to minimise the number of totes required per delivery and to keep minimise the storage area for empty totes. A Food & Delivery container, sized at 600 x 400 x 373 mm and developed especially for the retail e-commerce market, is part of BITO’s MB multi-purpose container series. It is important that a wide variety of products can be transported in the same container without wasting space.

Features to make it an ideal shipment tote for online grocery shopping include dividers that prevent items from slipping, tipping and leaking and ensure bottles or cups remain in an upright position. Equally important are insulation inserts made of EPP to provide a variety of dry storage or lower temperature areas for fresh produce, dairy products or frozen foods. Thanks to these inserts, it is possible to create several temperature zones within the same container. This is an advantage for small orders with only a few items per temperature range. Being able to ship these orders within the same container reduces the number of containers per customer.

Making containers work in any retail logistics role

Some of the bin and container designs offered by BITO to meet different retail warehouse and logistics applications include multi-purpose containers and containers formed from recycled material. For delivery purposes, BITO’s folding boxes and ‘stack & nest’ containers maximise storage capacity and minimise occupied space on empty return transport to cut freight costs.

Depending on the type of container there are many useful optional extras to further optimise the bin or container to its role in retail warehousing and logistics. For example, lids to protect contents from dust and dirt, which can also be security-sealed to prevent unauthorised access to goods. Dollies create convenient in-house transport. Label pockets protect labels to ensure clear barcode reading and identification. Bag holder bars, mounted on the upper sides of a container, are a particularly practical accessory for the booming online food retail business. Translucent containers with coloured attached lids offer an ideal aid for organising stock, while also helping to give visibility of products.

Having a ‘one stop shop’ supplier that can manufacturer and design racking and shelving as well as the bins and containers contained within means that both product groups are optimally adapted to each other to form a perfect bin shelving system. Did you know that many companies leave up to 30% of their storage space unused? Selecting the right bin or container will ensure the maximum use of shelving space. A retailer can spend time with BITO to find the right height configuration of storage and to select the right container to match its products.

For further information, visit www.bito.com.

Comments are closed.