Antalis Packaging’s National Sales Manager, Tom Reid, explores the common issues causing stretch film overuse and how to remedy them.

Stretch film is one of the major areas of plastic packaging use for companies involved in the packaging and distribution of goods, with the potential to contribute to high Plastic Packaging Tax charges.

Stretch film is one of the major areas of plastic packaging use for companies involved in the packaging and distribution of goods, with the potential to contribute to high Plastic Packaging Tax charges.

Naturally, many businesses are looking for ways to mitigate the impact of the Plastic Packaging Tax (PPT), with many considering switching to a film with 30% recycled content, which is exempt from the tax. Tom explains this may work for some, but it may not be particularly suitable for high volume users.

Tom clarifies, “The key to successful management of stretch film use comes down to machine calibration and matching the film to both the machine and the types of loads being wrapped.

Recently, Antalis Packaging worked with a manufacturer who was keen to switch to a recycled content film for transit packaging. Tom recommended they take advantage of Antalis Packaging’s free stretchCONSULT assessment. “It can be eye-opening for customers, especially when they see the savings potential”, says Tom.

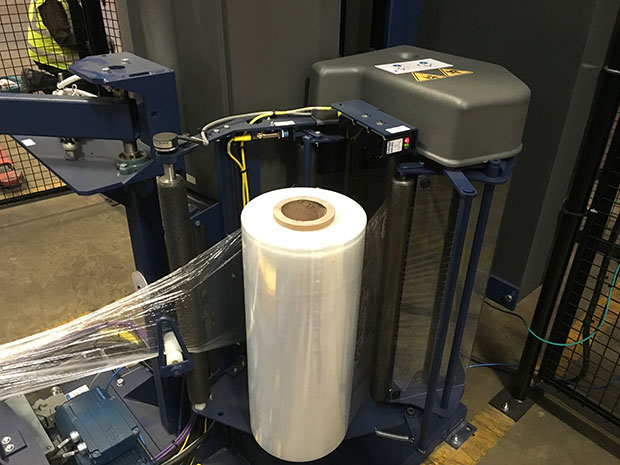

Antalis’ stretchCONSULT assessment is a four-step process: analysis, testing, documentation and implementation. Tom explains, “We audit both the film and the machine, carrying out an analysis of the products being wrapped; the intralogistics; the existing stretching technology and its performance and configuration; the film qualities being used; film consumption; the logistical requirements and most importantly the stability of the load.”

Tom continues, “Once the testing is completed, we provide customers with a report of the results, including details of the potential benefits and savings.”

The manufacturer typically wraps 60 1200 x 800 x 1200 pallets per day. To create a baseline for the assessment, Tom ran an initial test using the client’s existing set-up, including their 23 micron film. He discovered that the machine wasn’t calibrated correctly, resulting in the film not being tensioned, which resulted in poor load stability and the use of more film than necessary.

After optimising the machine calibration for the current film, Tom ran the test again. The improvement was immediate, while measurements confirmed that load containment force had increased from 2kg to over 4kg. Tom repeated the exercise using two alternative films; one, the 20 micron recycled stretch film the client was hoping to switch to, the other a high performance 15 micron film proposed by Tom. The high performance film consistently out-performed the other films in all tests. Compared to the baseline test results, it offered financial savings of almost 24%, a 35% reduction in plastic use, and a 35% cut in CO2. Based on the results of the assessment, the customer implemented the audits recommendations.

“Many customers dismiss switching to a high-performance film because of price per tonne – it is more expensive”. However, Tom adds, “once we show the customer how it’s possible to wrap significantly more pallets with high performance film, compared to films with recycled content or lower quality films, they are soon convinced. In the case of this customer, one tonne of 15 micron high performance stretch film would be capable of wrapping almost 11,000 pallets, compared to just over 7,100 of the 23 micron film they were using, and around 8,200 using the recycled content film. It’s a huge difference and significantly reduces the use of plastic, minimising the impact of the Plastic Packaging Tax.”

Tom concludes, “Every time Antalis performs an assessment, clients are amazed by the results and the savings to be made. Sometimes, customers don’t even need to change their film – once we have got the machine calibrated correctly, the difference in output can be staggering.”

For more information, please visit www.antalis.co.uk or contact Antalis on 0370 241 1466. You can also request your stretchCONSULT audit at ask.antalis.co.uk/film-audit.

Comments are closed.