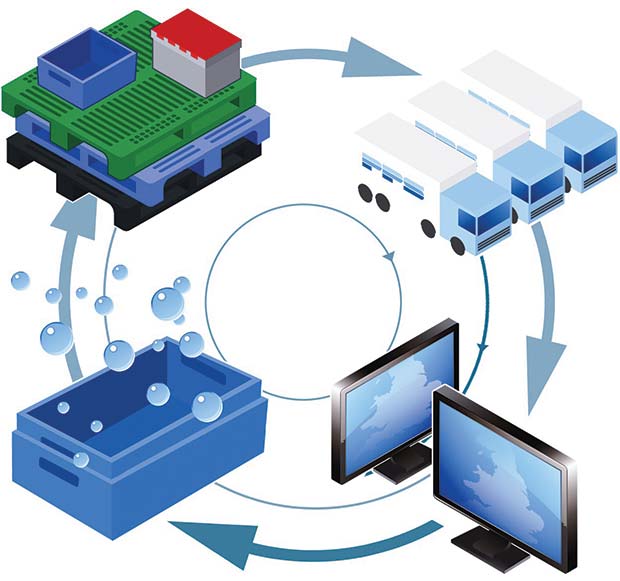

PPS offer ‘Total Equipment Solutions’ – supporting customers to assess their returnable transit packaging needs, identify the most suitable product and outsource the management and supply. This allows them to focus on their core business, providing a more efficient supply chain as well as cost savings.

PPS Midlands have established themselves over the years as one of the market leaders in providing total returnable transit equipment (RTE) solutions, which includes the supply and rental of plastic pallets, crates, containers and pallet boxes to clients throughout the UK and Europe. We provide our customers with the complete service that includes the rental, management, wash and repair of all types of returnable packaging.

The success of PPS lies in the efficient management of equipment. Our expertise in this field coupled with our own in-house developed IT tracking systems aptly named ‘ENABLE’, provides us with the management tool for us to monitor the movement of product and therefore, minimise equipment losses by accountability.

We have two modern and hygienic dedicated wash plants in the Midlands and Grimsby for washing all our own returnable packaging and also offer the facility to third parties on an ad hoc or contract basis.

David Peggie, Managing Director – PPS Midlands spoke to Warehouse & Logistics News.

WLN – First of all what does your role involve on a day to day basis? Has it changed since last year?

As managing director, I am responsible for the daily operations and direction of all aspects involved in the running of the business. However, in the last year, due to strengthening of the management team, this has allowed me to take on a ‘less hands on role’ and become more focused on planning the strategic growth of the business.

WLN – 2013 – How was it for you?

There is much to be positive about as companies continue to look for increased efficiencies in the logistic supply chain. Therefore, this has created a lot of growth for our Returnable Transit Equipment (RTE) services.

PPS has continued to invest in staff development and state of the art equipment and this continues to pay dividends. We have achieved 20% year on year growth over the past three years and have consolidated our position in the market place by agreeing long term contracts with a number of our major customers.

WLN – How has the pallets and containers category been performing this year? What do you see as the most significant recent developments?

In 2013, we have seen a continuation in the trend of customers recognising the benefits of returnable transit equipment as opposed to single trip packaging.

PPS has been promoting the advantages of returnable transit packaging for a number of years and whilst the carbon footprint reduction is currently in vogue, the major driving factor in the move to returnable plastic equipment is economics. In other words it may be an added benefit to claim you are reducing your carbon footprint, but the reality is that unless the exercise is also cost-effective no manager will sanction it. Where PPS has introduced their RTE equipment and management systems it has resulted in considerable cost savings for its clients.

Also, many companies are looking for a ‘one-stop’ solution when considering investing in returnable transit equipment and this gives us an added advantage. PPS can monitor and then collect used containers from third parties and bring them back to their plants at Measham or Grimsby, where we have state-of-the-art equipment to wash plastic crates, trays, tote boxes, collapsible boxes and plastic pallets to the BRC Storage & Distribution accredited standards.

WLN – Have you moved into any new business areas in the last 12 months?

Our main business continues to be the management of pallets, crates and box pools. We have taken our expertise in the management of our equipment pools into the crate hire sector. We provide crates, attached lid containers and roll cages to the removals, retail and distribution sectors.

WLN – What was your biggest investment to improve your business this year? What else have you done?

We have committed to a multi million pound investment to increase our RTE pool in all areas, in order to support new projects and meet increase business demands from existing customers.

The pre planning to increase our capacity in 2014 has resulted in us placing orders for new crate wash machines at both sites.

WLN – How are your existing products and services doing? Have you developed or upgraded your existing products and services recently?

We have promoted the use of our ‘ENABLE’ online tracking system into other market sectors, to assist customers manage their pools and eliminate substantial equipment losses.

We have also extended our internal equipment repairs facility, offering customers this repair service to support maintenance of their own equipment pools.

WLN – Have you launched any new products or services, and how are they performing?

We have launched our crate hire service aimed largely at the office removals and storage sector. Its performance in the last year has exceeded our expectations.

WLN – What’s been your company’s single biggest achievement in business this year?

The 50% increase in sales at PPS East. They supply Returnable Transit Packaging including plastic pallets and boxes mainly to the fish processing industry on the Humber, where 85% of all UK fish is processed. The growth has been driven as customers continue to see the cost and environmental benefits of moving away from single trip to returnable packaging.

WLN – What was your favourite moment of 2013?

The satisfaction and achievement of establishing an excellent management team for the future. They have made a positive commitment over the past 12 months, with their enthusiasm and a buy-in approach to the ambitious growth objectives for the future years.

WLN – Do you operate in any other countries besides the UK? How are you getting on there? Have you gone into any new territories recently?

We currently operate in Iceland, Norway and France. We are also in discussions at present with a similar equipment pooling company based on the continent regarding setting up a joint venture which will give us the opportunity to roll out our services into the European market.

WLN – Have you won any awards recently, or been accredited to any new standards?

We have continued to maintain our BRC accreditation in Storage and Distribution at both our sites, which is essential in connection to the supply of our blue chip customer base.

WLN – Can you tell us about your major projects this year, and what they involved?

We have outgrown our current facilities in Measham. The major project was identifying a suitable larger site to house the new plant and give us the space to continue to grow the business and support our current customers.

WLN – Can you tell us about your plans for 2014? Where do you see your business going?

We have had 20% year on year growth for the last 3 years, which we are targeting to exceed in 2014.

To facilitate this growth we take delivery in January of our new crate wash line that will more than double the current capacity of our Measham site. We have also invested at PPS East in a new box washer that will be delivered in April and will significantly improve efficiency and capacity.

![]() WLN – Are you looking at taking on more staff or expanding your premises next year?

WLN – Are you looking at taking on more staff or expanding your premises next year?

Yes, to support our continuing growth, we would expect to grow our workforce in order to support the increased volumes and maintain the high standard of service to our clients.

In the New Year we are moving to a new 76,000 sq. ft. facility, which is essential to give us the infrastructure to cope with our future growth.

WLN – Are you exhibiting at any major trade shows in 2014?

We are exhibiting at Foodex in March 2014, where we will be promoting our RTE products, washing and management services.

WLN – What other headline news from PPS can our readers look forward to reading about in Warehouse and Logistics News next year?

• The launch of our new site and our capital investment programme.

• The potential for setting up our first wash plant outside of the UK.

Phone: 01530 515333

Email: enquiries@ppsequipment.co.uk

Twitter: @PPSMidlands

Facebook: PPS Midlands

LinkedIn: PPS Midlands

Comments are closed.