Northern Manufacturing & Electronics 2019 returns to Manchester’s EventCity, from October 2nd to October 3rd. With maintaining competitiveness, honing competence and maintaining agility more essential than ever in these uncertain times for manufacturing, the show provides an outstanding opportunity to discover not just the most up-to-date industrial technologies, components and equipment, but also the latest ideas in business management and development.

Around 200 firms are expected to take part in the 2019 event, representing a well-rounded selection of major UK vendors, together with a selection of major international suppliers, offering visitors an opportunity to experience a much larger assortment of products and services than they would generally expect to find at a regional exhibition. The event is the Northern companion of the well-established and hugely popular Southern Manufacturing show, and like its popular sibling, its broad appeal offers visitors the opportunity to address multiple sourcing challenges in a single, time-efficient visit.

Around 200 firms are expected to take part in the 2019 event, representing a well-rounded selection of major UK vendors, together with a selection of major international suppliers, offering visitors an opportunity to experience a much larger assortment of products and services than they would generally expect to find at a regional exhibition. The event is the Northern companion of the well-established and hugely popular Southern Manufacturing show, and like its popular sibling, its broad appeal offers visitors the opportunity to address multiple sourcing challenges in a single, time-efficient visit.

Industrial hardware is well represented this year. One of the familiar names present is workplace storage equipment specialist, Bott. At Northern 2019 the firm will be exhibiting a selection of its heavy-duty, high-quality cubio range on stand C27. The sturdy, durable and reliable Cubio products can be put together to produce customised and versatile operating solutions which can be seamlessly extended as business needs change. Cubio also integrates with Bott’s wide variety of CNC & tool storage options, integrating LEAN, 5S and Six Sigma initiatives, promoting efficiency and output in the workplace.

Industore is the exclusive supplier of German-manufactured Hänel systems in the UK and Ireland. It will showcase sophisticated, vertical carousel technology at the exhibition. The Hänel Rotomat can be designed to specifications and tailored to a facility. It has error-free retrieval and fast pick rates, allowing manufacturers to maximise output and improve processes. The Hänel Rotomat is installed with brass brushes in the carrier arms to reduce ESD. The run speed is 0.15m per second and multi-functional storage carriers are available to suit different-sized electronic components. Other solutions for the electronics industry include Hänel ClimateStore and CleanStore for storing hyper-sensitive components.

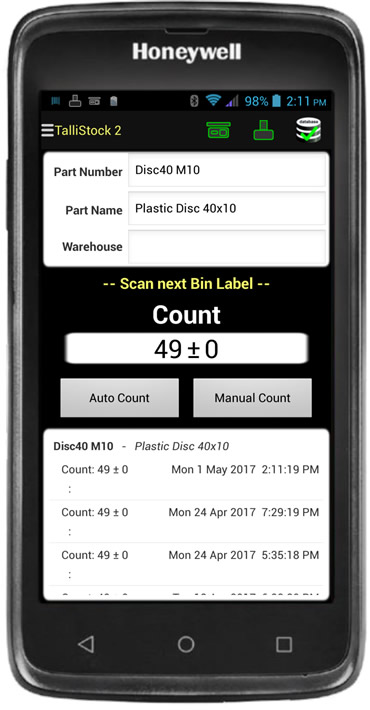

Stock control solutions on show include TalliScan, this year exhibiting its ergonomically designed Honeywell ScanPal EDA50 enterprise hybrid device. TalliScan’s handheld software has been upgraded to seamlessly incorporate the EDA50 built-in barcode scanner. Integrating ERP API and Android apps, users can access all business critical information in real-time, over wi-fi, as well as perform fast, automated stocktaking. The firm claims its automated counting function can count a parts-bin full of loose parts in only 10 seconds.

Stock control solutions on show include TalliScan, this year exhibiting its ergonomically designed Honeywell ScanPal EDA50 enterprise hybrid device. TalliScan’s handheld software has been upgraded to seamlessly incorporate the EDA50 built-in barcode scanner. Integrating ERP API and Android apps, users can access all business critical information in real-time, over wi-fi, as well as perform fast, automated stocktaking. The firm claims its automated counting function can count a parts-bin full of loose parts in only 10 seconds.

Software plays an important role in today’s manufacturing business. Visitors will have the opportunity to discuss what an MRP system can do for their business on the 123 Insight stand. The firm offers an innovative approach to introducing its products to potential customers, giving them access to resources such as demo videos broken down by job role, making it possible for each department to understand what the 123insight system can do. Suitable for all types, shapes and size of business from just two staff to over 4,500, the system offers tight integration with popular platforms such as Sage 50, Sage 200, Access Dimensions and Xero using Accounts Gateway.

Looking forward, it is clear that technology will take an even greater role in manufacturing, and consequently it’s vital that manufacturers understand how to leverage technology to remain competitive in a rapidly-changing manufacturing environment. Recent reports have highlighted the fact that the ubiquitous term “Industry 4.0 “ actually remains only vaguely understood by a significant percentage of industrial managers – with still fewer feeling confident enough to commit to capital investment at this time, even in certain knowledge that it will be vital to do so.

Northern Manufacturing 2019 provides a lifeline to those feeling overwhelmed by the rapid advance of technology through its involvement with several of the region’s leading industrial business groups and government-backed agencies such as Made Smarter and the Manufacturing Growth Fund. These organisations provide funding and advice to help businesses boost productivity and revenue by means of improved operational efficiency and digital solutions. The Manufacturing Growth Fund offers SMEs in the manufacturing and engineering sector impartial advice to help assess opportunities and barriers to growth. It makes advancement recommendations and supplies a grant towards the cost of bringing in specialist expertise for eligible projects. Made Smarter is the UK-government backed Industry 4.0 Accelerator initiative, which is designed to drive UK manufacturing growth, efficiency and transformation. The Made Smarter pilot aims to support manufacturers, engineers, makers and creators across the North West with the option of new solutions, from 3D printers to system integration and robotics. Its team of Enterprise 4.0 experts works with all types of manufacturers to help them stay ahead of competitors, meet increasing demands and operate efficiently.

Experts from Made Smarter and the Manufacturing Growth Fund will also make a key contribution to the show’s impressive complimentary industry seminar programme, providing specific advice on growing business, showing how other companies have done it and helping delegates into advice, funding and assistance that is available across the North West. Other highlights of the 2019 programme include sessions by award winning author, creator of the Lean Iceberg Model and partner at S.A. Partners, Gary Griffiths. Along with co-authors Professor Peter Hines, Pauline Found and Richard Harrison, Gary’s book “Staying Lean:Thriving, Not Just Surviving” won a Shingo Research and Professional Publication Prize in 2009 for its illustration of the experience of a multi-national company that successfully implemented Lean in its manufacturing and commercial operations. Andy Brunskill, Author of “TPM: A Foundation of Operational Excellence” will share his 11 step Model which can be used to deploy an effective, systematic Total Productive Maintenance (TPM) programme. The ever-popular Tim Scurlock explores further applications of Lean, looking at how Porsche improved quality, slashed labour hours, reduced lead time and boosted profit by means of the use of Lean Principles. Other sessions cover a wide quantity of topics, from CE marking to TPM and the Shingo model. Business topics addressed include practical problem solving and merger and acquisition strategies to maximise value. Attendance at all sessions is completely complimentary to visitors but must be pre-booked online at www.industrynorth.co.uk Further sessions include advice on mergers and acquisitions, CE marking, 3D print technology and advanced composite materials among others. A complete list of sessions is available online at www.industrynorth.co.uk

Admission to Northern Manufacturing & Electronics 2019 and on-site parking is free of charge with easy accessibility by road. EventCity is likewise easily accessible by public transport from central Manchester. To register online for complimentary tickets simply visit www.industrynorth.co.uk

Comments are closed.