Bringing Industry 4.0 to warehouse and logistics applications

Think of WERMA and you will probably imagine images of flashing lights, beacons and sirens found in so many diverse applications in Industry. Always a technology leader in the development of more sophisticated signal lights WERMA has most recently been developing innovative smart systems for process control and warning systems on the factory shop-floor.

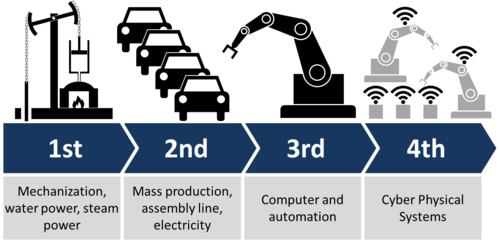

Indeed, many of the new product development work being carried out at the company has its roots in the trend which began in Germany of developing new systems to meet the challenges of Industry 4.0 compliance.

Industry 4.0 is a concept which captures the need to digitalise transfer of information and processes to remove “human machine interfaces” seen by their very nature as being a potentially vulnerable area and replace them with more automated computer driven systems. Here in the UK Industry 4.0 is still a really new concept but already another tag is being widely used to coin the concept more clearly – Smart Factory.

Two of the latest “smart factory” solutions from WERMA are designed to improve transparency of operation, identify bottlenecks and disruptions to the production flow and lead to improvements in service and efficiency by taking cost and wastage out of the operation.

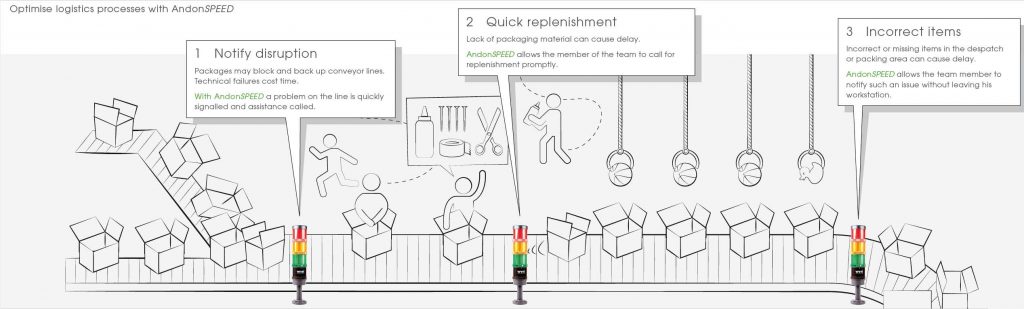

Andonspeed – speed up your logistics operation and reduce costs and delays

How does Andonspeed work?

A signal tower is manually activated by a member of staff on the shop floor to call for help from the appropriate service. By just pressing a button a signal light is illuminated on the workstation, clearly indicating the call for action required. The call for action can also be sent automatically by-email to the service concerned and response times can be monitored.

Intuitive and easy to use – Andonspeed is quick to install, the simple activation of traditional traffic light colours green, red and amber make it suitable even for unskilled or seasonal staff.

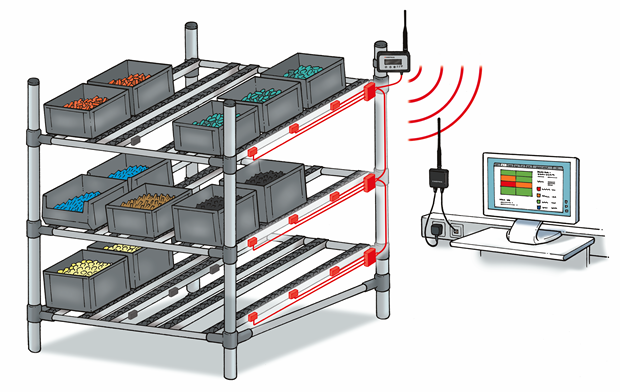

StockSAVER – Kanban replenishment system without cards

Few Kanban systems are completely free from errors and weak spots: the processing of Kanban cards can be delayed; cards can sometimes be mislaid leading to very little transparency in the operation. The introduction of scanners provides only partial relief to some of these issues, not least of all because often staff will “forget” to scan leading to incorrect bookings being made and shelves being incorrectly replenished.

The solution

With the help of WERMA’s StockSAVER many of the traditional Kanban issues can be resolved: stock withdrawals no longer have to be scanned and arithmetically calculated stock levels errors are removed.

Intelligent sensors on the FIFO racking give total transparency of stock levels and, thanks to the automatic call for replenishment, stock-outs and incorrect stock replenishment is excluded. The objective of the system is to halve the level of stock held line-side by reducing the traditional amount of safety stock being held there. Human errors in calling up for new material or the incorrect filling of shelves is eliminated.

Intelligent sensors on the FIFO racking give total transparency of stock levels and, thanks to the automatic call for replenishment, stock-outs and incorrect stock replenishment is excluded. The objective of the system is to halve the level of stock held line-side by reducing the traditional amount of safety stock being held there. Human errors in calling up for new material or the incorrect filling of shelves is eliminated.

Simple and easy retrofit solution

Sensors can be fitted simply and quickly to any FIFO flow racking system to detect the passage of all sizes of commonly used bins. Bin movements and the requests for replenishment are automatically transmitted wirelessly giving a transparency to the stock levels in the FIFO racks. This will enable a significant reduction in the requirement for safety stocks to be held there.

StockSAVER is simple to install and is easy to extend. Clear and simple Kanban displays keep Production and Logistics informed and enables the process to become more robust and less susceptible to errors.

WERMA UK Ltd

Tel: 01536 486930

https://www.werma.com/en/application/logistics_and_shipping.php

Comments are closed.