Over the past few years and in partnership with BVM Brunner of Stuttgart Germany Adpak have designed and developed product packaging solutions specifically for the E Com industry successfully installing many machines into various well-known brand named goods shipping warehouses. The higher end users where throughput is essential in particular the run up to Christmas peek volumes multiple systems have been installed, recently one customer has ordered five machines to be installed in a brand new facility which is due to go live in 2019.

The machine models comprise the standard Compacta range, then the Comtex 3G for inbound goods and the more flexible Comtex 4G usually supplied for outbound goods! All of the machines use recyclable polythene films which can easily be managed into other acceptable materials streams. The machines produce a bag which can be supplied in various colours with the choice of specific company logos printed on the film surface.

The machine models comprise the standard Compacta range, then the Comtex 3G for inbound goods and the more flexible Comtex 4G usually supplied for outbound goods! All of the machines use recyclable polythene films which can easily be managed into other acceptable materials streams. The machines produce a bag which can be supplied in various colours with the choice of specific company logos printed on the film surface.

Some unique features of the systems is the integration of address labelling and application of the label in an automatic operation. Scanning the product for height length and width the machine can then select the correct sized bag for random products being presented to the system. There is a verification protocol which identifies the packing slip and the product so that there are no errors in shipping goods to the wrong destination. On the outfeed of the machine there is a reject system which holds items that have label misreads and possible oversized packs. In some instances camera vision systems have been selected to ensure all the goods are correct and in good condition.

The process of recommending the correct solution for each customer can be intense as it is important that the customer invests in the right machine for his product packaging solution and to some degree future proofs the increase in volumes. The systems are sold in three stages, 1. manual packing from pick benches to the automatic bagger; 2. Semi automated system where the line packer selects the picking slip and then merges the product and pick slip together before transferring the unit to the fully auto bagger; 3. A fully automatic turnkey system where the handling of the product and merging of the pick slip is done without operator intervention and continues on to the bagging machine before the despatch to loading!

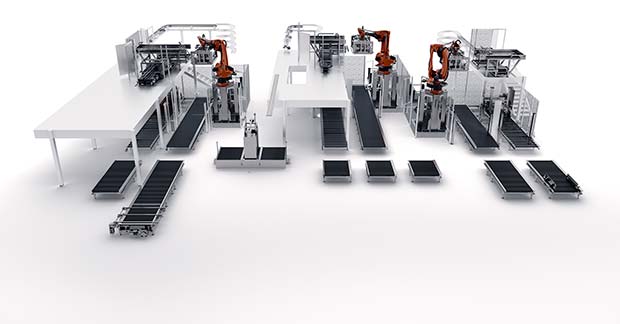

Adpak also provide a range of ancillary equipment to compliment the auto bagging machines. These consist of carton erecting, carton loading and closing, palletisation of the cartons fully automatically and at the end of the line through to a fully automatic pallet stretch wrapping machine. Our partner’s for these machine are Comarme and GPI. A full range of all our products can be seen on our web site www.adpak.co.uk

Adpak also provide a range of ancillary equipment to compliment the auto bagging machines. These consist of carton erecting, carton loading and closing, palletisation of the cartons fully automatically and at the end of the line through to a fully automatic pallet stretch wrapping machine. Our partner’s for these machine are Comarme and GPI. A full range of all our products can be seen on our web site www.adpak.co.uk

ADPAK

Comments are closed.