Pregis is a leading name in the US packaging industry with their high quality, protective packaging solutions and customer service. As part of an exciting expansion programme, the US packaging giant has begun trading in Europe through its UK and European facilities.

Pregis design and manufacture a comprehensive range of world leading protective packaging innovations for use in all sectors. Their high profile solutions include the UK’s leading environmentally friendly packaging brand, Easypack®.

Pregis design and manufacture a comprehensive range of world leading protective packaging innovations for use in all sectors. Their high profile solutions include the UK’s leading environmentally friendly packaging brand, Easypack®.

Manufactured in the UK, the Easypack brand has over 25 years of protective packaging heritage, along with numerous awards for packaging innovation. The range of totally green void fill and protective packaging technology allows customers to secure and protect all types of goods with 100% recycled, 100% recyclable and 100% biodegradable paper.

Unlike Kraft paper, no new trees are cut down in order to produce 100% recycled paper, so choosing a packaging source that protects trees from being destroyed, sends a powerful corporate and social message.

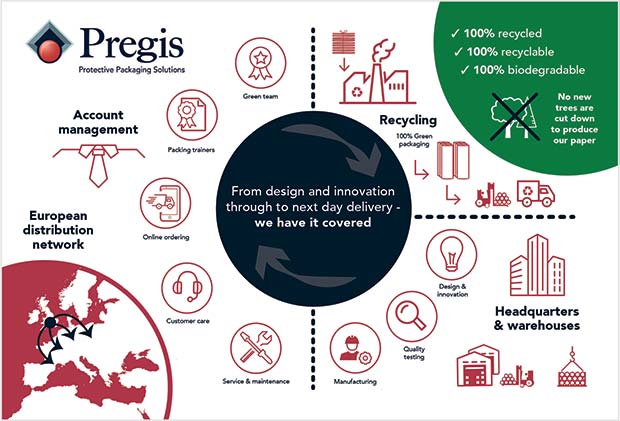

In addition to their high quality technology, Pregis supports its customers with a range of end to end services including consultancy, bespoke system design, care and maintenance, next day delivery of consumables, on-site training for operators and opportunities to be among the first to trial new innovations.

Headquartered in Hertfordshire, UK, Pregis plan to significantly grow its presence in Europe to become the ‘go to’ name for high quality protective packaging technology. Through its UK and European facilities and its continuously growing network of European distributors, Pregis will introduce many of the innovations that are already trusted and enjoyed by so many major US brands.

New void fill technology for 2018

Pregis protective packaging solutions are second to none when it comes to innovation, efficiency and reliability. They plan to launch a number of new innovations over the coming year which will follow the recent launch of three pioneering new void fill solutions.

The NEW Quantum™XT is a high speed void fill solution that firmly secures goods in transit with 100% recycled, 100% recyclable, 100% biodegradable paper. The system is ideal for fast-moving online retail goods, items that have unusual shapes or sharp edges and for box-inbox void fill.

The patented, bladeless tear-assist has been cleverly designed to offer operators effortless, safe, high speed tear off. In addition, the ergonomically designed and patented telescopic head design offers further flexibility by allowing operators to adjust its height, tilt and output direction.

With 400-660 metres of recycled paper on each roll, users can pack directly into the box continuously for faster output, with speeds of up to 1.8 metres per second. Paper rolls can be changed in seconds, maximising efficiency, and the rolls of paper can be easily stored, taking up minimal storage space either at point of use or in stock locations, freeing up valuable warehouse space.

The Quantum™XT can help to reduce packaging costs as output can be totally managed by its user friendly control panel. Users can pre-select exact lengths and speeds and then control the output with a foot pedal. The compact system can be wheeled to any location or affixed to a bench or work station for total convenience.

Pregis have also recently introduced two new Easypack solutions. The ‘pro’ range builds on the first generation technology of their market leading packmaster™, packsolo™ and packmate® systems. The new packmaster™pro is the most advanced void-fill and protective packaging system available today.

Using multiple grades of single or two-ply 100% recycled paper, the system converts it to 80 times its original roll volume to produce robust, paper cushioning. Delivering up to 26 metres of ready-to-use packaging per minute, the system offers outstanding reliability and efficiency.

Where space is premium, the new packmate® pro is a smart, slimline solution which has a host of benefits. Again, the system converts multiple grades of 100% recycled paper at high speeds of up to 23 metres per minute. The user-friendly control panel allows users to choose pack lengths and output speeds and it can be easily integrated into any packing operation.

Reliability is critical when demand is high

E-commerce continues to increase in demand and customer experience expectations, putting pressure on businesses; faster delivery, damage free shipments, effortless returns and zero shipping costs to name just a few. Fulfilment operations are faced with rising shipping costs coupled with the complexity of optimising operations, adapting for peak seasons, maintaining brand image and providing a safe environment for workers.

Solving these issues is an intrinsic part of the Pregis brand. Their understanding of the complexities of modern logistics is what drives the development of its superior technology. Safety and reliability are paramount and these standards ensure that customers at all stages of the logistics chain are never let down. Pregis will be showcasing their new innovations and giving packaging demonstrations at the eDelivery Expo at the NEC, Birmingham on 21-22 March – Stand F71.

For more information about Pregis, along with full product information please visit www.pregiseu.com.

Comments are closed.