A new initiative from Easilift Loading Systems has helped one key customer to implement further efficiencies in its core business of picking, packing and shipping goods.

When Easilift’s concept of a universal bridge plate lifting-table was presented to Ocado, they immediately understood the benefits it would bring to their operations and have since installed the product across their business. Since then the ‘Fandango’, as it has been nicknamed, has been a key feature in Ocado’s logistical depots.

When Easilift’s concept of a universal bridge plate lifting-table was presented to Ocado, they immediately understood the benefits it would bring to their operations and have since installed the product across their business. Since then the ‘Fandango’, as it has been nicknamed, has been a key feature in Ocado’s logistical depots.

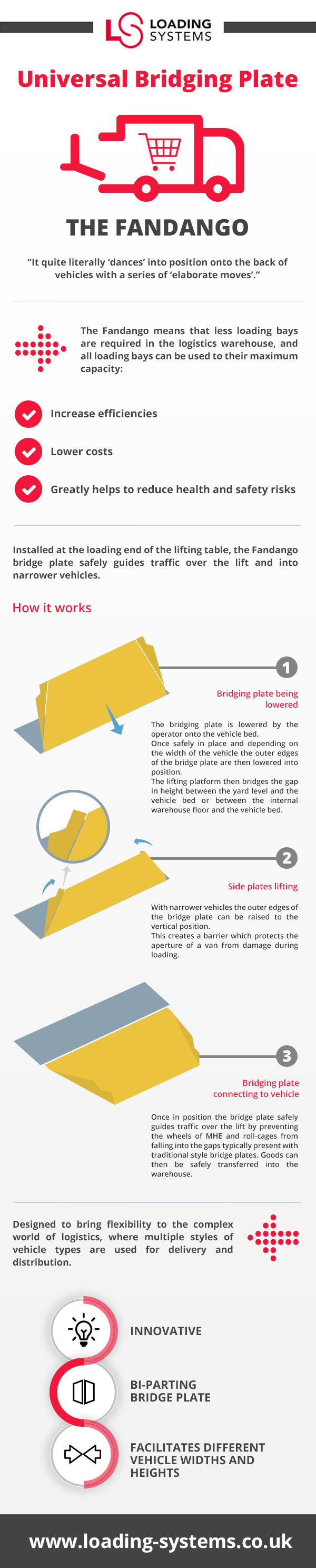

The Fandango bridge-plate was designed to bring flexibility to the complex world of logistics, where multiple styles of vehicle types are used for delivery and distribution. Traditional loading bays are unable to interface with today’s complete range of vehicle fleets which often requires dedicated loading bays to accommodate each vehicle type ranging from vans to double deck trailers.

Rob Fay, Managing Director at Easilift Loading Systems explained: “With the rise of e-commerce and dot-com shopping, there are huge operational efficiencies to be gained by being able to unload goods from a standard or double-deck trailer loading bay and then quickly change the configuration of the dock to load a home delivery van”

So what exactly is it?

This innovative lifting table features a bi-parting bridge plate which folds up at the outer edges to facilitate different vehicle widths. Installed at the loading end of the lifting table, the Fandango bridge plate also safely guides traffic over the lift and into narrower vehicles.

How safe is it?

With the outer edges of the bridge raised to the vertical position it creates a barrier which protects the aperture of a van from damage during loading; and at the same time the bridge plate safely guides traffic over the lift by preventing the wheels of MHE and roll-cages from falling into the gaps typically present with traditional style bridge plates.

What does this all mean for the logistics industry?

Because the Fandango facilitates the loading and unloading of any type of vehicle from a single loading bay, it means that less loading bays are required in the logistics warehouse. And instead of some loading bays standing idle, while queues are building up on others, then all loading bays can be used to their maximum capacity. ‘The Fandango’ lifting table increases efficiencies, lowers costs and greatly helps to reduce health and safety risks.

Rob Fay added: “The complexity of modern logistics is only going to increase as logistics operators utilise a more diverse range of vehicles for specific delivery patterns. Given the accompanying pressure to increase performance levels and cost-efficiency in logistics, our range of flexible loading bay products, including the Fandango, offers real benefits to logistics operators by improving the flexibility and efficiency of every loading bay.”

Loading Systems is the UK division of Loading Systems Group, a leading European business and market leader in the design, manufacture, installation and on-going service, maintenance and repair for a full line of industrial doors and dock equipment.

Loading Systems Group has been one of Europe’s leading manufacturers of industrial doors and loading bay equipment for over 50 years. Our products and services are distributed throughout Europe, the Middle and Far East by 11 Loading Systems offices and a network of more than 40 authorised distributors.

Here in the UK, Easilift Loading Systems Ltd has played a pivotal role in the success of the Group. We manufacture, supply, install and service industrial doors and loading bay solutions across the whole of the UK.

Easilift Loading Systems work with the UK’s leading supermarket chains, logistics and warehousing companies, dotcom retailers, plus manufacturing, automotive and aviation organisations. The UK company employs over 50 people and has it’s head office based in Huddersfield, West Yorkshire.

Company website – www.loading-systems.co.uk Tel: 0800 160 1965

Rob Fay is available for interviews and for further information please contact Andrea Munt on 07714 733198 andrea.munt@loading-systems.co.uk

Comments are closed.