Manual pallet stretch wrapping is fine for occasional use and unconventional loads, but an automated turntable wrapper is essential for frequent use.

Capital costs are sometimes cited as the reason for not automating, but when all factors are considered, the investment is soon justified.

Capital costs are sometimes cited as the reason for not automating, but when all factors are considered, the investment is soon justified.

Manual wrapping is physically demanding, with extensive use increasing the likelihood of operator strain injury, resulting in sick leave, employee dissatisfaction and poor workmanship. Further disadvantages are the longer time taken to wrap a pallet, the inefficient use of skilled labour on a time-consuming, mundane task, greater use of film and inconsistent results.

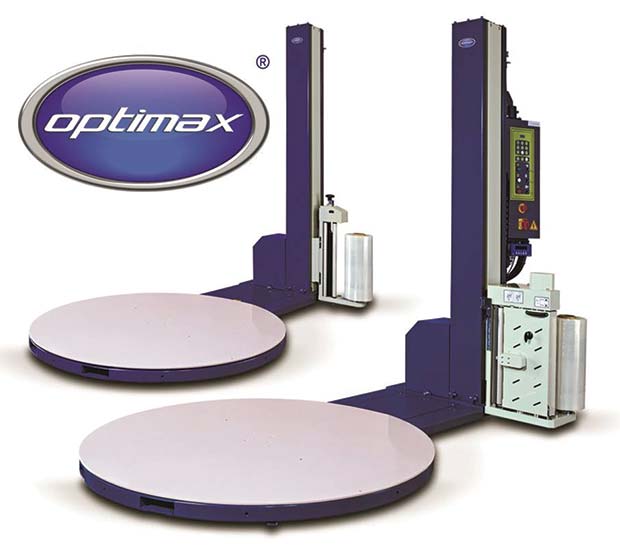

Optimax®, an established and trusted brand in the field of packaging machinery, currently offers two models in its range of turntable stretch wrappers, with additional models coming onstream later this year.

The Optimax® PSW002 gives the operator a selection of wrap configurations, programmable through a rotating control panel. Power pre-stretch elongates the film to four times its original length; this drastically reduces film usage and achieves greater load stability. An optional ramp enables pallets to be loaded onto the turntable with a pallet truck, and with automatic turntable orientation at the end of the cycle, pallets are loaded and offloaded from the same direction.

The Optimax® PSW001 is lighter on features and uses a spring brake mechanism to tension the film, so is more suited to high volume, basicconfiguration wrapping than the PSW002. The optional ramp may also be fitted to the PSW001 for pallet truck loading and automatic turntable orientation is standard.

OPTIMAX®

Tel: 0333 005 9603

Comments are closed.