In response to customer feedback, Yale® Europe Materials Handling has developed a bespoke two-tier fleet management programme specifically tailored to each client.

Whether a multinational company or a small scale, regional fleet operator, the right fleet management package will be designed with the individual business in mind. Vince Cooke, Business Development Manager for Yale said, “In partnership with its global network of dealers, Yale is well placed to provide a fleet management programme to its customers, so that these customers can shift their focus to their core business.” “This programme is in direct response to feedback from customers – from multinational companies who prefer to deal with the manufacturer to small fleet operators who want local support but with a single point of contact – about what is important to them.” The Yale fleet management programme offers two tiers: Tier 1 – dealer-managed fleet management and Tier 2 – Yale-managed fleet management. Whichever tier is selected, Yale will provide an account manager who will work with the customer to design a package tailored to the needs of that business. Within that package, they will be asked to choose from options including:

Whether a multinational company or a small scale, regional fleet operator, the right fleet management package will be designed with the individual business in mind. Vince Cooke, Business Development Manager for Yale said, “In partnership with its global network of dealers, Yale is well placed to provide a fleet management programme to its customers, so that these customers can shift their focus to their core business.” “This programme is in direct response to feedback from customers – from multinational companies who prefer to deal with the manufacturer to small fleet operators who want local support but with a single point of contact – about what is important to them.” The Yale fleet management programme offers two tiers: Tier 1 – dealer-managed fleet management and Tier 2 – Yale-managed fleet management. Whichever tier is selected, Yale will provide an account manager who will work with the customer to design a package tailored to the needs of that business. Within that package, they will be asked to choose from options including:

• Purchasing or leasing

• Financing

• Single point of contact for servicing

• Servicing for all makes / models – periodic / full maintenance

• Fleet-preferred labour and parts pricing

• Short-term rental

• Performance reporting

• Periodic reviews

• Advice on optimising operations

Cooke added, “We have the experience and expertise to help our customers save money. Not only do we have an extensive network of dealers providing truly local support, we will take away the hassle of fleet management.”

Yale Vision

Yale Vision

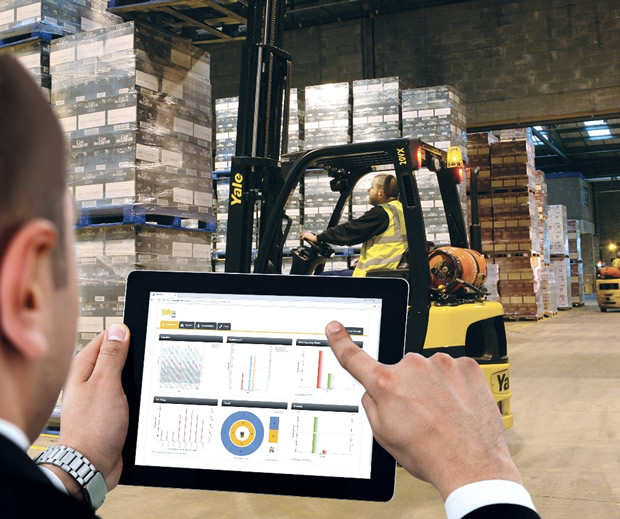

Operational costs and safety are major considerations for all materials handling businesses, and fleet monitoring is now a crucial remit of a fleet manager’s role. Yale Vision is a telematics system designed to track performance data through wireless technology, helping to increase the optimum performance of a truck while reducing maintenance and repair costs. The Yale Vision Wireless Asset Management system offers a host of benefits, all of which provide tangible cost savings to the business. Functions include:

- Control of operator access

• Verification of pre-shift checklists

• Asset protection

• Event reporting and logging based on CAN-Bus gathered information

• Cost management

• Reduced downtime control

• Cost tracking wirelessly through www.yalevision.com accessed via a desktop, laptop or tablet.

Paul Wells, Aftermarket Manager for Yale said, “Companies who have invested in Yale Vision have seen an increase in operator accountability, which has led to an improvement in operating behaviour. The benefits include reduced damage to both equipment and stock.”

I-Rent

I-Rent

Equally important to the evolution of the fleet manager’s role has been the introduction of I-Rent, an industry-first tool for calculating when – and if – new tyres are needed.

Wells added, “I-Rent allows dealers to move away from the ‘one set per year’ mentality when including tyres in contracts. The inexact nature of this approach can result in either unrecoverable losses, or artificially high rates being applied.”

Since Yale introduced their I-Rent programme, alongside the supply of Trelleborg Pit Stop Line (PSL) tyres as standard on counterbalance trucks, customers immediately noticed the savings on forklift operating costs.

Since Yale introduced their I-Rent programme, alongside the supply of Trelleborg Pit Stop Line (PSL) tyres as standard on counterbalance trucks, customers immediately noticed the savings on forklift operating costs.

I-Rent is an industry-first rental calculator and contract tool, dependent on the use of PSL tyres which feature an orange wear band to identify the optimum time to replace them. I-Rent utilises more than 400 application factors and several thousand historical tyre change data sets to accurately predict the wear rate of tyres during the course of a truck rental agreement.

It is estimated that forklift users without the benefit of this feature discard tyres, on average, while 25% of their usable life remains. Thanks to this innovation, extra mileage is gained without compromising on the effectiveness of the tyre.

How it works:

• Customers buy the I-Rent product

• A calculator accurately predicts the actual wear on tyres

• System allows for different types of driver, operations and surfaces, which are likely to impact on . tyre wear, to be taken into consideration

• 400 application factors

• Wear-band allows user to visually identify when to replace the tyre

• Across both rental and sales customers

• Improves efficiency, serviceability, simplicity and low cost of ownership

• Can include tyres on all-in maintenance contracts

Whatever the business operation, the fleet size or the application, there is a Yale fleet management programme that can help ensure the most cost-effective materials handling equipment solution.

For more information, visit www.yale.com where you can locate and contact your nearest dealer.

Comments are closed.