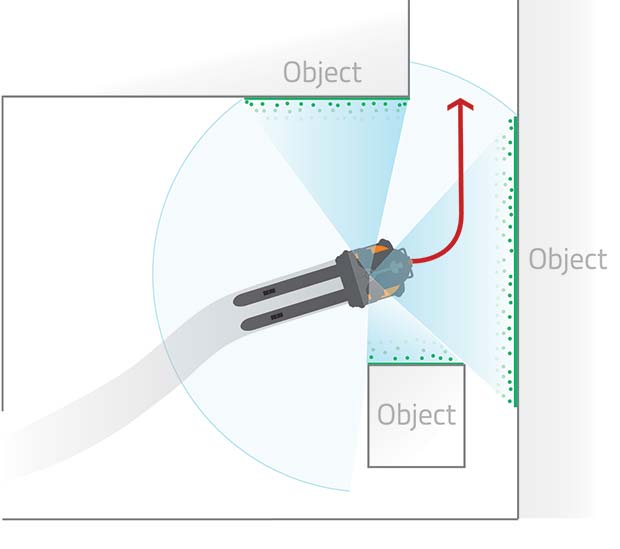

Already offering a wide range of automated trucks for different applications with the Autopilot models, Toyota now expands its automated solutions offer with a new navigation technique. Quicker to set up and with a simplified installation it delivers a flexible solution that is suitable for a wide range of applications. This navigation method utilises recognisable reference points or landmarks within the warehouse, such as walls, racking and fixed objects, to calculate the truck’s location.

Natural navigation is a lowercost alternative for warehouses where the surroundings remain fairly constant. The truck can utilise the existing environment to navigate without the need for extra equipment such as reflectors, avoiding extra cost and installation of additional equipment. All trucks from the Autopilot range are currently equipped with reflector navigation, a navigation method in which consistent and highcontrast targets, reflectors, are added to the environment.

Natural navigation is a lowercost alternative for warehouses where the surroundings remain fairly constant. The truck can utilise the existing environment to navigate without the need for extra equipment such as reflectors, avoiding extra cost and installation of additional equipment. All trucks from the Autopilot range are currently equipped with reflector navigation, a navigation method in which consistent and highcontrast targets, reflectors, are added to the environment.

A unique benefit of Autopilot trucks from Toyota is the fact that the navigation system can support either reflector or natural navigation, or both. In the case of dual navigation, one area of the layout may use the warehouse environment as a reference, whilst another area uses reflectors, which allows the Autopilot to switch seamlessly between natural and reflector navigation.

“We are excited to introduce this navigation method to our range which allows us to support our customers with a wider offer and more cost-effective automation solutions. We are also unique in offering a combination of two types of navigation in one system,” says Frank Hasleden, Logistics Solutions Manager at Toyota Material Handling UK.

TOYOTA MATERIAL HANDLING

Comments are closed.