By Andy Pretious, Sales & Marketing Manager at Automated Packaging Systems.

The advantage of small and medium enterprises (SMEs) over larger companies is frequently down to the ability to be more flexible, agile and responsive.

The advantage of small and medium enterprises (SMEs) over larger companies is frequently down to the ability to be more flexible, agile and responsive.

Business growth depends on being able to diversify and adapt the offer to meet market demand, often in a relatively short space of time. SMEs build their success on relationships, reliability and delivering quality. It’s therefore important to have a packaging solution that reflects this in the dayto- day service provided to customers. Equally important is managing cost and investment in equipment that can meet these needs. While value for money may be front of mind, there are a number of other factors that need to be taken into account when specifying packaging equipment, not just in the short term, but looking ahead and investigating wider market trends to ensure a solution is not only fit for purpose immediately, but scalable to ensure it works hard for the business well into the future.

EVALUATING THE MARKET

It is at this time of year, when many business are putting the finishing touches to future capex budgets that consideration of the return on that spend needs to be made. By putting in the legwork to anticipate future needs, you can examine not only what equipment will deliver in terms of output and service to existing clients, but also what new market opportunities it will open up.

With a surge in the construction, nuclear and automotive markets, there has been knock-on growth across a number of associated markets in the past two years. To gather insight into the long-term possibilities market predictions, policy decisions and industry reports can all provide valuable information as to how marketplace drivers are likely to impact on current company capabilities as well as stimulating ideas on how to ensure that the business can stay ahead of the curve and maximise any fresh opportunities that present themselves.

For example, in February 2017, the government released a white paper stating the need to build 250,000 additional homes each year which is set to bolster, if not boost, the growth in the construction market. This undoubtedly represents an opportunity for manufacturing and construction markets, but businesses must ensure that they are ready. With growth in nuclear generation and construction predicted to continue into 2020, this is also likely to create growth in the industries that provide materials into those markets.

These market insights can inform business decisions and help plan for anticipated requirements for both growth with existing customers and new opportunities. For example, the number of bags needed per annum will not only impact on the method of bagging but potentially the number of machines required.

Once calculated, and the method of bagging whether manual, semiautomated or fully automated bagging is decided, this calculation can then be up-scaled to reflect planned future scenarios based on commercial growth objectives. This will ensure that systems can cope easily with sudden and planned fluctuations in demand.

PLAN FOR THE FUTURE

Not having the right tools for the job required can have a significant impact. Organisations must specify based on the number of product lines they run, coupled with how often they change these lines, or whether they need these product lines to run concurrently.

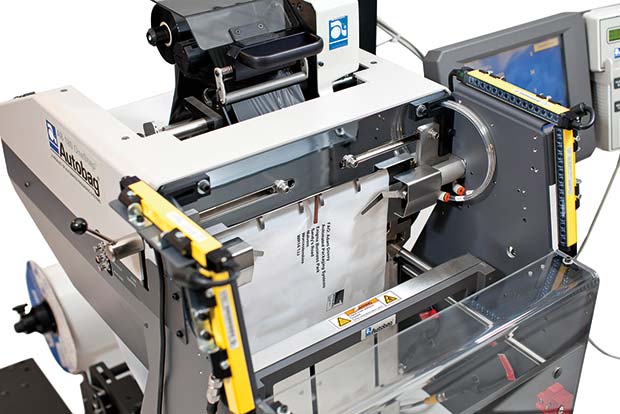

Table top packing machines are portable, and one step up from hand bagging, bringing speed and consistency to hand load applications. Solutions such as the Automated Packaging Systems’ Autobag PS125 can operate at speeds of up to 25 bags per minute and is a straightforward table top design that has a plug-and-play configuration. This level of solution is ideal for low to mid-volume packaging operations. Another element for consideration is printing and labelling. SMEs specifying a packaging solution need to consider whether there is any requirement to include labelling and printing in their offering to customers. Increasingly, customers are looking to increase transparency throughout their supply chains with labelling playing a critical role in this processes.

Even if an immediate requirement has not been identified, it’s vital to review the potential future requirement should the business or industry grow substantially or develop its technology. For example, a packaging machine like the Autobag AB 180 OneStep can pack up to 30 bags per minute whilst incorporating printing of highresolution text, graphics and barcodes. This solution is ideal for short production runs and build-ondemand operations.

AUTOMATED PACKAGING SYSTEMS

Comments are closed.