When leading global adhesive specialist, Bostik, was looking for an efficient method of transporting its adhesive products to its industrial and construction manufacturing clients, it turned to Structure-flex for an appropriate bulk handling solution.

Bostik ‘smart’ adhesives are used extensively in the manufacture and assembly of products in a wide range of sectors such as packaging, tapes, and labels as well as being used globally in the construction of new buildings and refurbishment projects in flooring, tiling, waterproofing, sealing, and insulation.

Bostik ‘smart’ adhesives are used extensively in the manufacture and assembly of products in a wide range of sectors such as packaging, tapes, and labels as well as being used globally in the construction of new buildings and refurbishment projects in flooring, tiling, waterproofing, sealing, and insulation.

Andrew Krawiecki, Supply Chain Manager at Bostik, explains: “Our products can be found almost everywhere. From cradle to grave, from home to office, from food to transport, the company’s bonding systems are used in countless applications.

“We transport over 40 tonnes of adhesive a week to manufacturing clients for use as a constituent part in their own products and need to ensure that there is a safe and stable way of delivering the adhesive to them in perfect condition.”

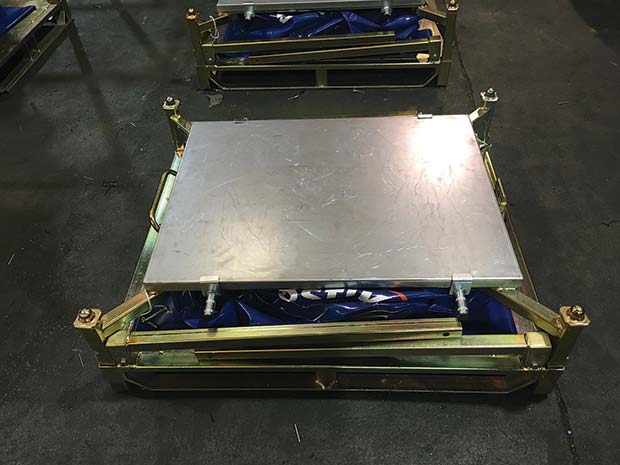

The answer was Structure-flex’s Eclipse system, a 1,000 litre capacity liquid container designed specifically to meet the packaging needs of non-hazardous bulk liquid handlers. Each container consists of three essential elements; an inner disposable polythene liner, an outer reusable PVC bag and the metal frame itself.

The Eclipse system offered Bostik the opportunity for efficient transportation within a reusable, strong, yet flexible system with lower cost empty carriage returns and reduced space requirements for collapsible unit storage.

Andrew continued: “One of the most important features for us was the ease of discharge. The base flap and ratchet assembly enables almost 100% discharge of the adhesive so there is extremely little waste.”

Andrew continued: “One of the most important features for us was the ease of discharge. The base flap and ratchet assembly enables almost 100% discharge of the adhesive so there is extremely little waste.”

The disposable inner liner is another useful feature of the Eclipse system that many users find invaluable. It helps reduce cleaning costs as well as allowing the system to be used for a number of different products without the risk of cross contamination.

“The latest order we placed was for 100 containers for our UK wide transportation,” continued Andrew. “Over the years, Structure-flex has modified the liner and we have had a very professional working relationship with them. “We’ve been very pleased with the Eclipse system and I’d definitely recommend it for similar applications to ours.”

The Eclipse system is one of a wide range of heavy duty reusable bulk packaging methods offered by Structure-flex for granules, powders and liquids, which excel in harsh environments and demanding applications.

STRUCTURE-FLEX LTD

Comments are closed.