Exertherm ‘in-drawer’ MCC 24×7 Thermal Monitoring solution provides increased uptime & reduced maintenance downtime for critical conveyor motors Exertherm the world’s no1 provider of 24×7 Thermal Monitoring systems for mission critical electrical infrastructure, now enables continuous hotspot detection of critical power connections in each MCC drawer. As a result, annual /periodic inspections requiring downtime can be eliminated.

E-commerce continues to grow exponentially, and with it comes customer expectation of fast delivery. This puts enormous pressure on fulfilment centres, and the logistics companies responsible for the delivery of product, particularly at peak times.

E-commerce continues to grow exponentially, and with it comes customer expectation of fast delivery. This puts enormous pressure on fulfilment centres, and the logistics companies responsible for the delivery of product, particularly at peak times.

A vital part of the logistics process is the ability to move / sort packages as quickly and efficiently as possible via motorised conveyors. These motors are thus the potential Achilles heel of these highly sophisticated systems.

Operational uptime for each motor is essential to ensure co-ordination of complex conveyor systems. As a consequence, a malfunction of a motor on the conveyor system can quickly lead to costly delays and even shutdown of time critical core operations.

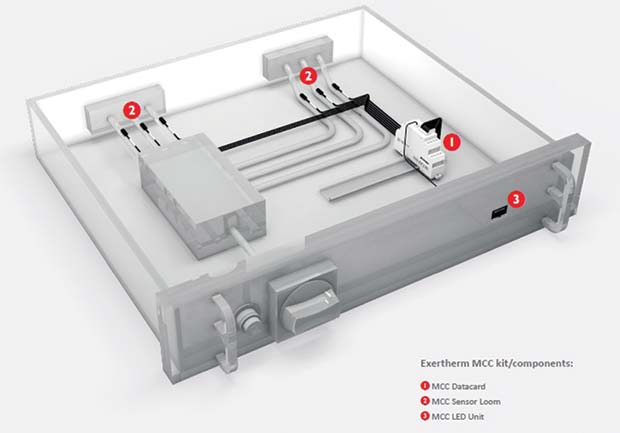

A common cause of such outages are compromised electrical terminations at the motor control centre (MCC), where individual drawers control the operation of a specific motor. The problem is that the critical in / out power connections are located at the rear of the drawer (see picture), making it impossible to inspect them during uptime operations. For 24×7 logistic facilities, this means coordinating complex downtime inspections.

Innovative technology from Exertherm the world’s No1 provider of 24×7 Thermal Monitoring systems for mission critical electrical infrastructure now enables continuous hotspot detection of each drawer from as little as $150, and with no need to continue periodic inspections requiring downtime, payback is fast.

The system is sold in kit form per drawer, with status indicator LED, and the ability to send an alarm to the system head end to alert which drawer and specific termination is overheating. Other features include phase imbalance alarms (a 10°C differential across phases can half the life of a motor), and optional Modbus comms.

Suitable for new build or retrofit to existing equipment, this new leading-edge technology is already being adopted by global OEM’s and blue chip organisations. Find out how Exertherm can increase uptime and reduce maintenance costs in your organisation today.

EXERTHERM

Comments are closed.