Aetna Group, the world’s largest manufacturer of industrial wrapping machines, came to the attention of A1 Towbars in 2014 after its management team made the decision to implement a significant upgrade to the company’s packaging system. The Sheffieldbased company manufactures an extensive range of high quality vehicle towbars.

The company was purchased in 2006 by the present management team headed by Chief Executive Mark Terry, and has its manufacturing base in Sheffield, with offices in Cambridge and Jersey. Its 35 employees design and manufacture over 350 different products and components which together make up the company’s range of towbars which are supplied mainly to independent towbar fitters and fleet vehicle outfitters.

“Every towbar we sell to the customer is designed and manufactured by us in our Sheffield facility,” says Mark Terry. “Sales are growing, and in order to continue to increase our share of the UK marketplace, we have made some heavy investments since we acquired the company, which have taken the company from the lower end of the market to the top end for both quality and service. However, where we were still under performing was in getting the product to the end user in pristine condition 100% of the time. We felt that even a small percentage of failures was not good enough.”

The problem lay in the packaging. The product leaves the factory in a box containing several component parts with small fitments.

The unassembled towbars are an awkward shape with some loose parts capable of piercing the packaging if roughly handled, and the product occasionally reached the recipient damaged or with parts missing in transit.

Mark explains, “Having raised the standards of the products and other parts of our process, we couldn’t allow this weakness to let us down, and needed to address this problem with some urgency. We changed our carrier to TNT, which in my opinion is the best in the business, a move that immediately improved handling techniques. We then made plans to invest in a semi-automatic machine which would provide us with a more secure packaging solution. These two investments, we felt, should ensure that our products arrive at their destination in good condition.

“Our first attempt at purchasing a wrapping machine was a disaster,” he went on to say.

“Having done our homework, we ordered one and waited for delivery. And we waited… and waited. In the end, we gave up, cancelled the order, and went back online to do more research. Fortunately, through a referral, we found Aetna UK which manufactures the type of machine that would suit our needs perfectly, so we contacted the company straight away.

“We spoke on the phone to Paddy McCartney, National Sales Manager at Aetna UK, who really couldn’t have been more helpful. He and his colleagues gave us extensive advice, and in the end, we bought from drawings without actually seeing the machine ‘in the flesh’. Unfortunately, delivery of our wrapping machine was going to take longer than planned, but Aetna UK came to the rescue once again and provided us with a temporary one to get us started. What fantastic customer service! Aetna UK dug us out of a big hole, and we were very appreciative.”

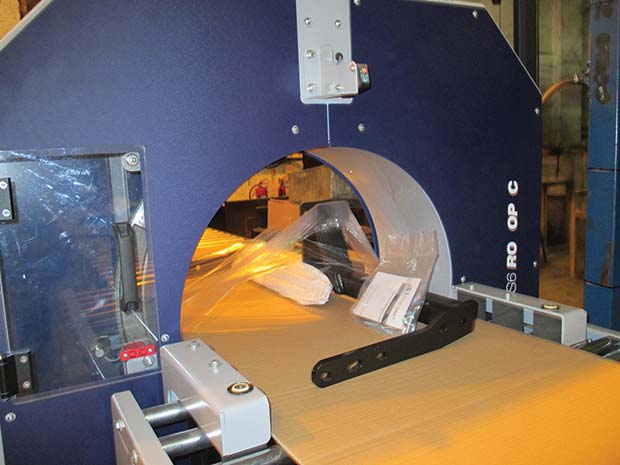

Aetna UK’s Robopac Compacta SPR is playing an integral part in A1 Towbar’s success story. Individual components are manually picked and placed on a cardboard bed, and they then travel along a roller feed into the wrapping machine itself where they are automatically secured to the bed by stretch wrapping. The ends of the cardboard are folded and the components are placed, as a whole, in a box for final dispatch to the customer.

“Not only has the Robopac Compacta SPR given us a secure packaging solution, it also affords us economy of scale,” Mark finishes. “7% of our product cost is in packaging, and the machine has reduced our need to stock a range of 39 different sized boxes. Because the product is now secure within the box, we now need only 9 different sizes.

“Towbar manufacture is a seasonal business, which means that we are extremely busy at certain times of the year. Using the Robopac Compacta SPR allows us to speed up the packaging process, enabling us to pack between 140 and 200 boxes on a daily basis.

“All in all, we couldn’t be happier with Aetna UK and its machine. It does exactly what we wanted it to do, it’s easy to operate, our customers are getting their products in an undamaged and complete state, so are delighted, and the company is making economies. We have had tremendous service from Aetna UK, and I wouldn’t hesitate to recommend the company and its products to anyone who asked.”

Kaylan Senior

Tel: 01234 825050

Email: kaylans@aetna.co.uk

Comments are closed.