Gebhardt-ECS has been appointed to implement a dynamic multi-level storage and picking system at the Lear Corporation factory at Coventry. The factory manufactures high-quality car seats for leading automotive manufacturers in a just-in-time approach for the final car assembly lines.

Due to the large range of designs and optional items required for seats for premium car brands currently, the conventional mezzanine-equipped storage and picking system at the factory had become inefficient and expensive to operate. In addition, more and more space was needed to store the required number of items.

Due to the large range of designs and optional items required for seats for premium car brands currently, the conventional mezzanine-equipped storage and picking system at the factory had become inefficient and expensive to operate. In addition, more and more space was needed to store the required number of items.

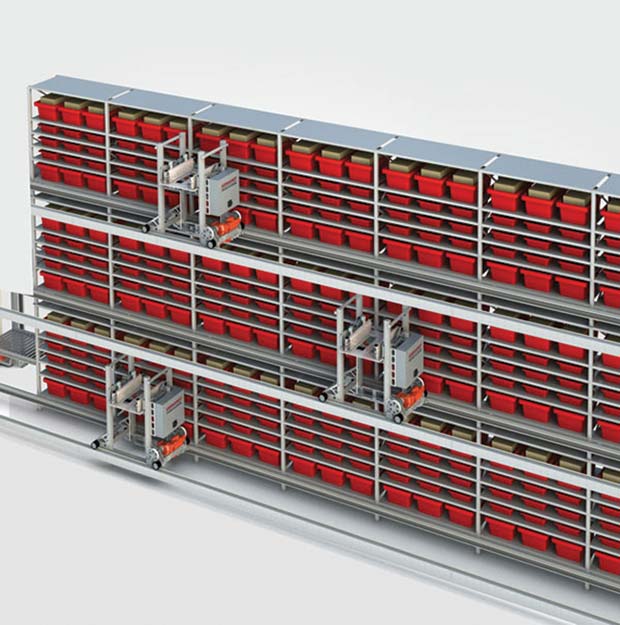

The solution developed by Gebhardt-ECS includes the use of 14 Storebiter MLS multi-level shuttles to handle 18,000 storage trays. Each MLS shuttle can access four levels of trays, which significantly increases the quantity of trays that can be stored compared to conventional single-level shuttles.

The project, which also includes mezzanines, tote conveyors and a Gebhardt Storeware warehouse control system, is currently being installed and is due to come into operation at the end of this year.

Tel: 0115 987 4363

Email: sales@gebhardt-ecs.co.uk

Comments are closed.