Our first question asks about the specific documentation that should be received following an installation of racking. Then we have a question on what clearances should be left between pallets and bays of racking.

Installer Documentation

Installer Documentation

Q. What documentation should we get from the installer to say it complies with SEMA guidelines, and is there a SEMA course that will go through this and explain about SWL notices and what information should be on them?

A. First of all if you move rack and rebuild it in a different configuration (different beam pitches are often involved) then you will likely have changed the carrying capacity of the rack and to allow your operatives to use it safely you will need to establish the new carrying capacity and ensure your operatives understand its limitations. Normally this is done by preparing a new load sign and attaching this to the end of the run or bay of racking. This should be professionally printed and bear the name and contact details of the person or organisation who calculated the carrying capacity so they can be contacted easily for any clarifications necessary.

To do this calculation access will be needed to the manufacturer’s load tables and the technical ability to use them. Generally manufacturers of racking are reluctant to release such load tables without knowing that the person who will use them has the technical ability to do so effectively. The most convenient way of obtaining such load signs is normally from the original supplier who will usually provide these though may wish to inspect the rack beforehand to ensure it is built correctly.

Given the number of different rack suppliers and number of different product lines they sell none of the commercial courses available from SEMA, or any others to our knowledge, cover the matter of load calculations. If for some reason you do not wish to use your original supplier or if you do not know who it is you may need to use one of the commercial consultants operating in this field who would be able to carry out such an inspection independently and provide appropriate load signs. This will be a more expensive option and any reputable consultant needs to carry substantial product liability insurance given that a collapse involving a £30 load sign could result in a six figure insurance claim. Getting it right is therefore important both practically and financially. If you need to the services of a consultant who offers these services please make contact and we will provide some options.

If an installer is reconfiguring racking for you this then depends on the terms of contract between your two organisations. Some installers carrying out this work make a point of stating on their order acknowledgment that they are providing skilled labour to work under your instructions only. Responsibility therefore rests with yourselves and you are unlikely to get any certification.

In other situations the order might acknowledge they are changing the racking and then we would expect them to source and provide load signs for the new configuration and in which case they are responsible for leaving a satisfactory system on finishing the work. Normally the supervisor will walk the site and inspect the rack on completion and provide a completion certificate which he will sign and invite you as client to countersign.

Mind the Gap

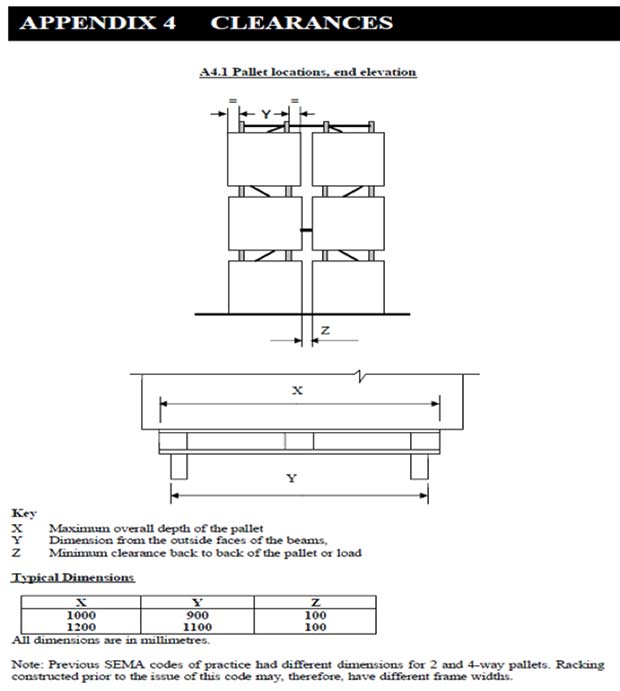

Q. What is the required distance between racking – I have two sections that are back to back with a 200 mm plus gap between them – is there a legal standard?

A. The gap between two runs of racking depends upon the goods/pallets being stored and the presence or otherwise of obstructions in the gap.

The SEMA User code gives recommendations as below, you should be able to download this document from:- www.sema.org.uk/guides.asp –

There should be a minimum gap (Z) between the loads of 100mm

The dimension between the racks depends upon whether or not the load overhangs the pallet but, if we assume that there is no load overhang, the frame width should be 100mm less than the pallet dimension i.e. 50mm pallet overhang front and back. So, for a double entry rack you will normally get a minimum dimension of 50 + 100 + 50 = 200mm between the runs.

If the load overhangs the pallet by a greater amount then the gap should be increased accordingly.

If there are any obstructions in the gap e.g. parts of the building, longitudinal rack bracing, sprinklers etc. then the gap should be increased accordingly.

The gap between two racks is normally controlled by run spacers which are fixed to the uprights at approximately 2.5m vertical centres, however, please be aware that not all racks are fitted with run spacers.

SEMA is delighted to be working with WLN on the storage Question and Answer Column which is published in WLN on a monthly basis. On the WLN website is a list of previously published columns which we hope you find useful.

Please note that SEMA Users Club members also have access to a comprehensive range of additional storage related questions and answers.

SEMA Annual Safety Conference 2015 – a date for your diary

The 2015 SEMA Safety Conference has been scheduled for Thursday, 5 November; the venue will be the National Motorcycle Museum, Solihull. For full details and a booking form contact SEMA at enquiry@sema.org.uk

SEMA Technical Enquiries

We hope you find the above articles, and those in previous editions, interesting. If you have a query send it to us by fax or email and we will do our best to have it answered by one of our technical experts.

SEMA Rack Safety Awareness and Inspection Courses

SEMA runs a one-day safety course on Rack Safety Awareness and Inspection. These courses are aimed at end users, giving an in-depth look at the need for inspections, how to conduct an assessment and what actions to take when this is completed. These courses are normally held at the SEMA headquarters but arrangements can be made to hold them at the delegates’ premises.

SEMA Approved Rack Inspectors Qualification

This qualification is aimed at professionals who conduct rack surveys as an integral and significant part of their duties. It involves delegates in undertaking an in-depth SEMA Course, together with an examination and practical assessment. CPD will be an important part of the qualification, demonstrating to end users that SEMA Approved Inspectors maintain a high professional standard.

SEMA USERS Club

Members receive newsletters, access to specialised events and discounted rates on publications and codes of practice.

Comments are closed.