Easypack found a gap in the market back in 1992 for high performance cushion void fill packaging for transportation of goods for the industrial sector. We took the idea and ran with it, developing and manufacturing ever-improving products to support high end industries.

With a UK headquarters based in Hertfordshire, the Group has expanded into Europe with subsidiary companies based in France, Germany and the Benelux. These outlets service all other major European territories, which has contributed to Easypack winning the prestigious Queens Award for Enterprise – International Trade on no less than 3 occasions.

With a UK headquarters based in Hertfordshire, the Group has expanded into Europe with subsidiary companies based in France, Germany and the Benelux. These outlets service all other major European territories, which has contributed to Easypack winning the prestigious Queens Award for Enterprise – International Trade on no less than 3 occasions.

We continue to elevate our business and take pride in our high quality products, customer care and service.

WLN – As the Environmental category experts, how has the category been performing in the last 12 months? What are the major trends and developments?

Enquiries leading to the continued growth of our paper packaging solutions over oil and chemical based products such as plastics, foam, polystyrene and polythene is evidence that environmental concerns are back on the map.

Since the inception of the company, we have only offered 100% recycled paper, promoting its recyclable and biodegradable properties. Development of all our products is driven by the need to reduce the effect of transit packaging on the environment. Manufacturing our paper from sustainable recycled sources means that there is no requirement for new trees to be felled.

Today, green credentials are not only important to our clients, the retailers and distributors, but also to the end users and consumers. How many times have you been frustrated to receive a parcel with messy polystyrene chips and the headache of responsible disposal? We believe that even small changes will make a big difference – changing how we pack can have a hugely positive environmental impact.

WLN – What are your core products and services: what are you best known for providing?

Easypack are renowned for providing high quality in-the-box-packaging solutions with exceptional environmental credentials. This is backed by excellent customer care and a ‘can do’ attitude to providing bespoke solutions for smaller retailers and national distribution centres alike.

Our aim is to significantly reduce packing times and waste by creating solutions that work for everyone, from the packer through to the end consumer. Our in-the-box paper packaging is more protective than other forms of packaging fillers; reducing damage in transit and in turn reducing costs.

As a manufacturer, our customers receive a dedicated service and direct communication with us, rather than having to go via a third party. This not only saves time but also enables us to provide a unique service and product to each individual client.

WLN – What developments or upgrades have you made to your core products and services in the last 12 months?

In the long history of Easypack we have always had a culture of continuous improvement, which continues to this day in our product design and business operations. 2014 has been no exception with additions to our range and many enhancements to existing solutions. For example we have introduced new recycled paper grades that are economical, versatile and provide maximum strength in-the-box, as well as new system electronics and a digital user interface with focus on efficiency and simplicity.

To further enhance our green credentials we have achieved ISO 14001 accreditation. This maintains our commitment to the environment and supports our customers with their environmental targets.

Despite the increase in system placements across the Group the continued investment in product development and our customer care team have resulted in the lowest ever number of reactive service visits resulting in maximum up-time for our customers.

WLN – What makes you the ‘go to’ supplier in your area of expertise?

We have developed our knowledge and experience over 22 years to become the UK leader for in-the-box void fill and protective packaging. With our headquarters based in the UK and offices and distribution centres located all over Europe, we have the capacity to cope with a vast range of products and all sizes of organisation.

Transit packaging has developed considerably over recent years. Previously industries transported products protected by polystyrene chips, bubble wrap and polythene. Not deemed effective or green, the industry is now looking for a more protective, environmentally sustainable solution – Easypack’s paper packaging solves this problem.

WLN – Have you launched any new products and services in the past year? How are they performing?

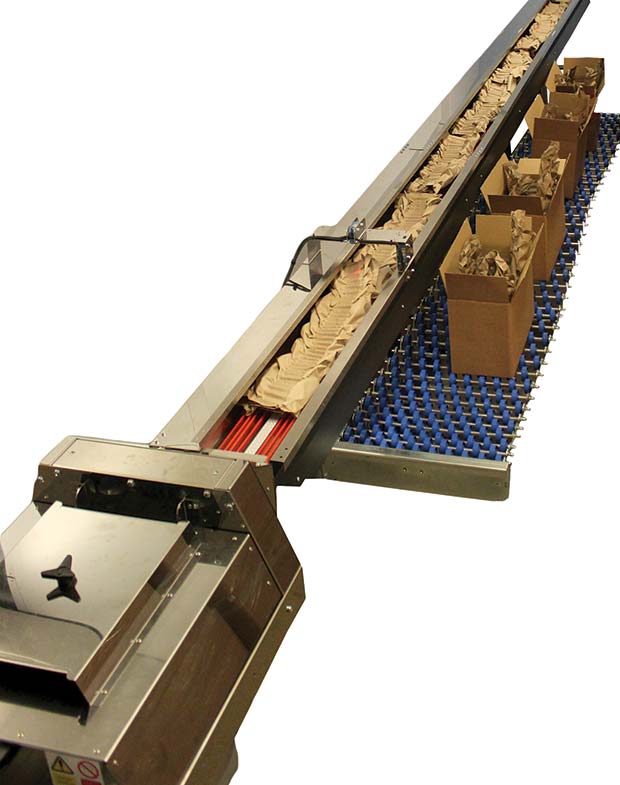

Working in partnership with a leading electronics distributor in Paris, Easypack has launched an innovative automatic paper delivery system enabling numerous packers to be fed protective paper pillows, simultaneously, from just one Packsolo system. Due to its unprecedented success this Product has been further enhanced and is now available across the full Easypack range.

Continued development has resulted in 3 new paper grades being launched to match market requirements. During 2014, ongoing investment and research will enable us to launch brand new products aimed at a new sector of the void fill and paper protection market in 2015.

WLN – Which industry sectors are your customers in?

The online retail sector has been a massive growth area over the past few years and the demand for strong, cost effective and sustainable packaging is increasing month on month.

Easypack packaging products have been designed with the customer in mind and working in harmony with all industry sectors. We can package all types of product from furniture, car parts and industrial components through to pottery, CDs and books. The customer base of Easypack is diverse, from Swiss watch manufactures through to suppliers of agricultural machinery spares.

WLN – Can you tell us about your latest major projects, and what they involve?

We are continuing to pursue our green business goals by developing technology that enables our systems to operate more efficiently with reduced power consumption, but with no loss of performance, thus helping our customers reduce their carbon footprint.

Easypack is also heavily investing in the development of more efficient paper mediums that provide higher yields to drive down the cost of packing without compromising product protection.

WLN – Have you made any big moves recently in terms of investment in the business, recruitment and so on?

WLN – Have you made any big moves recently in terms of investment in the business, recruitment and so on?

Easypack has grown year on year and 2014 has been no exception. We recently acquired a new distribution center, which is our 3rd new site in 3 consecutive years. The additional facility will enable us to operate in excess of 50% more production and storage capacity, whilst also assisting with full disaster recovery support and helping meet the expectations of the ‘next day world’.

We have structured our UK commercial team to enable us to build an even closer relationship with our customers up and down the country. Finally, we have invested in an ergonomic component storage system allowing full integration with our state of the art SAP management software, resulting in significant improvements in order lead-time.

WLN – What was your company’s single biggest achievement in the last year?

2014 has seen a record year for Easypack sales, increasing all over Europe. Most notably the UK has outperformed the rest of the Easypack Group territories. The move into our third new distribution center highlights this continuing success for the company and one of our biggest achievements this year.

WLN – What are your plans for 2015? Are you planning to bring out any more products or services, move into new markets or enter new countries?

The Company has a range of exciting new products scheduled for launch in 2015. Our team has been working hard to develop an enhanced solution for the void fill market.

As mentioned above we are also continuing our commercial restructuring to supply the increased demand from Internet retail and to support our continued expansion plans. We pride ourselves on our customer service and believe that having a personal approach is important. We have an expanding, dedicated team of regional sales people, working to visit customers on a more regular basis to further improve communication and strengthen relationships.

WLN – Are you exhibiting at any major trade shows this year?

WLN – Are you exhibiting at any major trade shows this year?

With such a large presence in Europe, we exhibit at numerous major events throughout the year. We understand the importance of connecting with people and exhibitions allow us this opportunity, showcasing our products, their benefits and demonstrating how they work.

2015 will see us exhibiting at the following shows:

• Empack – Hamburg & Hertogenbosch

• Logimat – Stuttgart

• Transport Logistic – Munich

• Fachpack – Nurnberg

• Logistica – Utrecht

• Spring Fair – Birmingham

• Packaging Innovations – Birmingham

• Home Delivery World EU – London

• eDelivery Expo – Birmingham

• Ecommerce Expo – London

• Intralogistics – Paris

• Europack – Lyon

• Empack – Belgium

WLN – What are your predictions for the industry in 2015?

With continued growth of online sales in the UK and the online retail phenomena taking hold in Europe, we predict the future to be a bright one. More high street names will continue to invest in an online arm of their business leading to more innovation for logistics and transit packaging. We have just achieved a record year for sales across Europe, with double digit growth predicted for 2015.

WLN – What other headline news from your company can our readers look forward to reading about in Warehouse & Logistics News in 2015?

WLN – What other headline news from your company can our readers look forward to reading about in Warehouse & Logistics News in 2015?

We are extremely proud to have won the Queens Award for International Trade for the third time back in 2013 and hope to do so again in 2015. Winning such a prestigious award recognises all the hard work and dedication that the team has put in to creating such competitive eco products.

Phone: 0845 8380 168

Email: info@easypack.net

Web: www.easypack.net

Comments are closed.