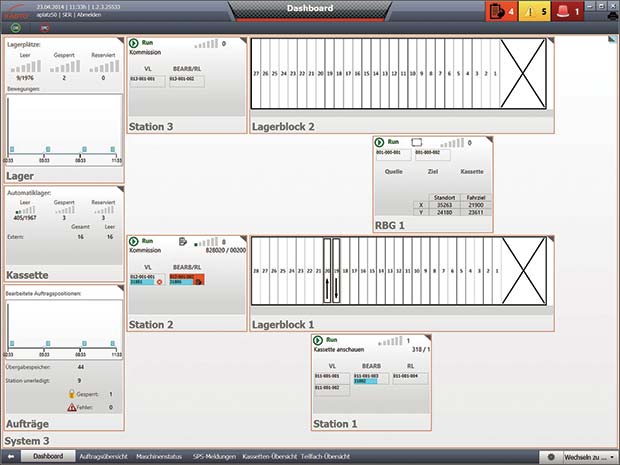

To complement its range of storage systems and controls, KASTO has upgraded its warehouse management software from KASTOlvr to KASTOlogic and in so doing has further improved its functionality. Core functions consist of an intuitive graphical user interface, an interface to the customer’s host computer system and a dashboard for overall visualisation of warehouse management.

In addition to the standard module, customers can choose from various additions. One is material flow, which oversees dynamic random storage and real-time restocking and provides 3D simulation and statistical information including of gantry movement. Bottlenecks are detected and the system’s full potential can be exploited by adjustment strategies.

Inventory management is broken down into three sub-groups: logistics, for optimising routes within the warehouse; production, for providing an overview of orders and machine utilisation; and manual storage, for managing non-automated areas of a warehouse and manually operated equipment.

Machines and handling systems with a higher level of automation may now be included and comprehensive statistics are available for system analysis. An automation function allows an even better overview of connected production machinery, whether it is for sawing, sheet metal profiling, pressworking or inter-machine handling.

One of the first companies to use the new KASTOlogic software is family-owned metal stockholder, Weinmann Aach AG in Dornstetten, which uses four KASTOunicompact honeycomb systems with a total of 7,000 cassettes. The stores, which include goods-to-man commissioning stations, hold steel, stainless steel and aluminium bar, tube and profile. They ensure short picking times and their compact design optimises space utilisation.

KASTOlogic controls the honeycomb storage units, clearly displaying all processes from receipt of goods to shipping. The exchange of data with other systems, such as the host computer at Weinmann, ensures a high level of transparency. The system’s functions include automatic order processing, batch management, inventory management and remote diagnostics.

As with the controls on each individual store, the warehouse management system is operated via a graphical user interface developed by KASTO. Previously, they featured different interfaces but over the last few years, user experiences have provided insights into how system operation could be improved.

Andreas Stark, deputy manager of storage software development at KASTO explained, “A lot has changed in recent years, particularly in terms of operating concepts.

“A user interface must be simple and intuitive to operate – like a smartphone, for example. This gave us several ideas for how we could improve our user interface, which we decided to completely overhaul.”

The new interface is both easier to use and more user-friendly. All functions can be found quickly and easily, while system statuses are clearly displayed and monitored. To help resolve problems, KASTO has included improved help functions. It means that employees can work more efficiently, training times are shorter and production planning is streamlined.

Tel: 01908 571590

Email: sales@kasto.uk.com

Comments are closed.