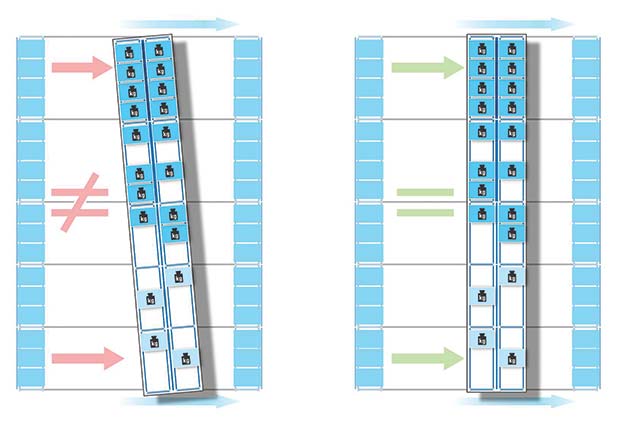

Bito enjoyed a successful CeMAT 2014 exhibition in Hanover, where it showed its full range of storage, picking and transit packing solutions. Among an array of new solutions designed to significantly enhance the warehouse was a continuous separation control for Bito’s PROmobile mobile racking systems. In pallet or cantilever design, mobile racking offers extremely high storage capacity by eliminating the need for access aisles. However, if the racking units on their mobile bases do not run parallel at a 90 degree angle to the guide rails, due to uneven loading, the tracking elements in the rails can slip, causing wear. Bito’s new control, called PROmobile Synchro, adds separation control that provides a solution that will minimise this wear on wheels and rails. The user therefore incurs lower service costs and significantly less downtime.

Underlining its position as a leading exponent of FIFO (First In, First Out) storage, Bito showed its enhanced PROflow pallet live racking system, which makes it easy to implement FIFO. Instead of relying on the usual braking rollers, Bito’s PROflow Active System uses intelligent, motor-driven rollers. These support the pallet on approach, and automatically decelerate it in the channel. This means even defective pallets and pallets with sensitive goods can travel safely through the channel without risk of collision or breakage.

Bito has given its PROmotion Shuttle a complete facelift, equipping it with improved sensors, an optimised mechanical system and a lighter battery. This battery-operated, remote-controlled deep lane vehicle, which enables pallets to be effectively handled and conveyed within the racking, has already successfully proved its worth in numerous applications.

The Bitobox XLmotion was another new development to address the growing trend towards automation in warehouses. This container’s new full-perimeter base ensures high stability and quiet running on automated conveyors – reducing noise is an increasingly important factor in warehouses operating automated conveyors. With dimensions of 599 x 399 x 270 mm and a volume of 53 litres – remarkably high compared with competitive products – the Bitobox can be loaded with up to 50 kg. When full containers are stacked, the bottommost container can support 250 kilograms.

Visitors to BITO’s stand were also able to see its Grid Shelves. Compatible with Bito’s standard shelving systems, these specially perforated shelves are ideal for shelving systems that have to be fitted with sprinklers. The rectangular holes on the Grid Shelves allow water to easily drain in the event of an emergency and goods do not end up standing in water. This has a positive effect on the cost of insurance premiums. Their permeability to air also makes them ideal for use in cold stores while their permeability to light makes for a brighter working environment.

All of these innovative products, will be available to UK customers through Nuneaton-based BITO Storage Solutions.

Operating out of its headquarters in Nuneaton, Bito Storage Systems is the UK Subsidiary of BITO-Lagertechnik Bittmann GmbH, which has its head office in Meisenheim and specialises in storage and factory facilities and order-picking technology. The company provides shelving and shelving systems, storage and order picking systems, bins and containers, storage equipment and accessories for all branches of industry. Customers are provided with standard products, which are developed and manufactured in-house, and project-specific solutions from a single source.

Comments are closed.