In the warehouse of a major direct sales jewellery company, pickers place jewellery boxes on two conveyors that transport them to packing stations. A 1-D barcode on each box is read by ID readers located above the conveyor and based on this identification, each box is diverted to the correct packing station. The laser scanners in place were designed to read A & B quality barcodes, which the jewellery company had planned to begin putting on its boxes. However, the company was unable to get the A & B quality barcodes from their manufacturer and the scanners were only able to read 96.5% of the barcodes, requiring two fulltime people to handle the read failures. Cornerstone Automation, the systems integrator involved in the project, collected all of the boxes that could not be read in a day and asked Cognex, a leading developer of vision based ID readers, if they could offer a solution. Cognex’s DataMan 302L vision-based reader read every one of the read failures. The new ID readers have increased read rates to above 99.9% and saved 75 hours per week in read failure handling.

Barcode reading challenge

The jewellery boxes are approx. 3 inches wide by 3 inches deep by 1.5 inches tall. A 1-D barcode is placed by the manufacturer on the front end of the lid of the box so it faces forward although the quality of these barcodes varies significantly. When a wave of orders is run, the dispensers automatically eject the boxes needed to fill the wave onto the conveyor. No attempt is made to orient the barcodes in a specific direction. This automated system is highly efficient but it depends heavily on the ability of the barcode reader to read the barcode on nearly every box travelling down each line at a rate of about one per second.

Move to vision-based technology

The jewellery company asked Cornerstone Automation to improve the read rates on the poor quality barcodes on the line. Since the line was originally installed, substantial improvements in vision-based ID reading technology have provided new cost effective options in addressing this challenge.

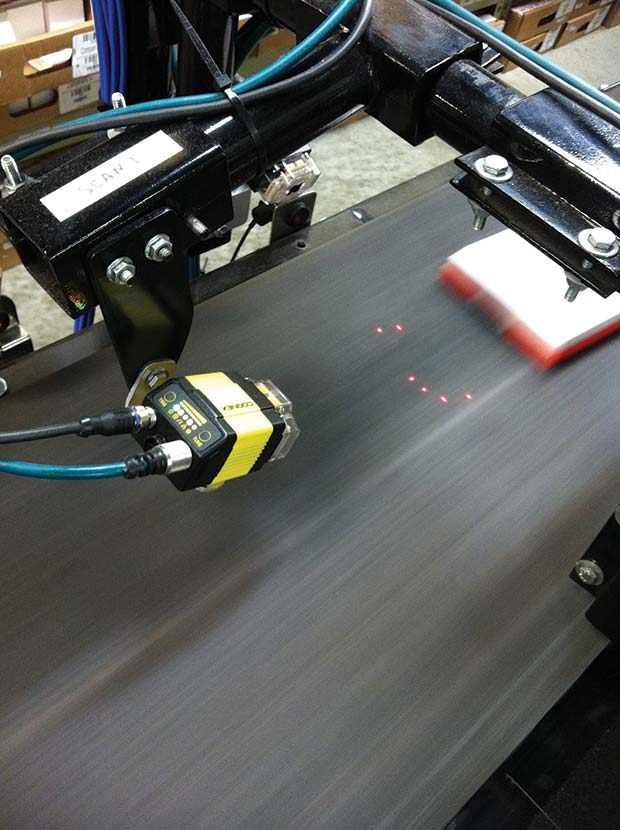

Cornerstone selected four Cognex DataMan 302L fixed-mount ID readers which were set up in four different directions at a distance of 12 to 16 inches from the box at a 20 degree angle to the conveyor belt. The ID readers were configured using group triggering so that all four readers acquire an image simultaneously and then combine their individual read results to form a composite result.

Cornerstone selected four Cognex DataMan 302L fixed-mount ID readers which were set up in four different directions at a distance of 12 to 16 inches from the box at a 20 degree angle to the conveyor belt. The ID readers were configured using group triggering so that all four readers acquire an image simultaneously and then combine their individual read results to form a composite result.

The new readers provide a 99.9+% read rate. This dramatic improvement in read rates has made it possible for the two people previously assigned to manually read the labels, to be moved to more productive tasks. The end result is that the jewellery direct seller has eliminated a major headache and significantly reduced its distribution costs.

Cognex

Comments are closed.