Conveyor Systems Ltd (CSL) offer a unique combination of engineering skills and a wealth of experience in providing materials handling solutions tailored to suit individual requirements across a wide range of industries.

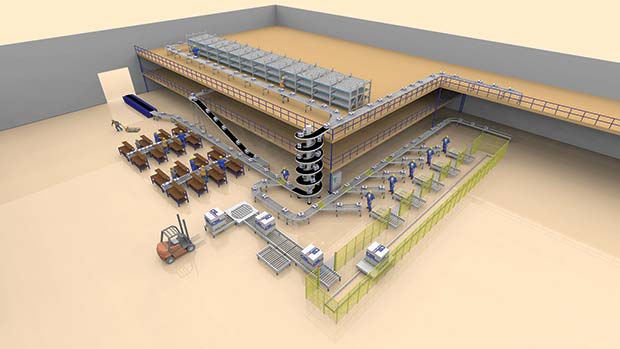

CSL provide the optimum solution to customer’s handling requirements through the use of innovative 3D design, supply and integration of proven quality equipment to achieve the most cost effective conveyor system.

CSL provide the optimum solution to customer’s handling requirements through the use of innovative 3D design, supply and integration of proven quality equipment to achieve the most cost effective conveyor system.

These 3D designs can be viewed as CAD drawings or real-time video clips to enable customers to evaluate proposals in terms of throughputs and product sortation.

CSL offer simple, cost effective modular conveyors to interface and integrate with other OEM handling and packaging equipment, live storage, interfacing with robotic handling/palletising systems, etc – through to installation and commissioning of complete automated turnkey materials handling systems with integrated controls and software.

Steve Graham – Managing Director – Conveyor Systems Ltd spoke to Warehouse & Logistics News.

WLN – First of all, what does your role involve day to day? Has it changed since last year?

As MD of a close knit team, I am responsible for the daily operations and direction of all aspects involved in the running of the business.

Although I continue to be actively involved is Sales, Jim Farquhar who joined us last year as Sales Manager is focusing on developing new business as we continue to look forward to controlled expansion of CSL.

WLN – 2013 – How was it for you?

As part of our strategic plan to achieve controlled growth for CSL, we moved to larger premises, investing in state of the art 3D design equipment and appointed a new dedicated sales manager in 2012. As a result, we can now confidently claim that this is starting to pay dividends in 2013.

CSL can be pleased of its achievements and progress. In the first four months of our financial year, commencing 1st July 2013, we have already seen our order value increase and exceed the previous 12 months turnover, which was also a very good year.

WLN – How has the Conveyors category been performing this year? What do you see as the most significant recent developments?

While there are big challenges facing many traditional businesses and retailers, strong growth in e-commerce is continuing to drive demand for strategically located distribution space and highly efficient handling systems.

With reported improvements in the economy there is a growing optimism that consumer spending will be on the increase. Therefore, companies are now committing and gearing up, particularly with an eye to online shopping, so that they are prepared to meet the anticipated demand.

This has a knock-on effect as companies look to invest in storage and automation, with particular emphasis on order picking, packing and sortation systems. With CSL’s experience and reference installations across a wide sector of industries, the opportunities and future is looking very positive for 2013 and beyond.

WLN – Have you moved into any new business areas in the last 12 months?

CSL continues to be involved with supporting fresh produce businesses that are looking to speed up and improve order picking efficiencies, minimize errors, supplying even fresher produce on time and ensuring product traceability, whilst operating with the minimum number of staff.

However, as e-commerce expands CSL’s involvement with other sectors has grown, with new and repeat business from existing customers for systems involving order picking, packing and sortation within the music/DVD entertainments, ironmongery, hand and powered tools, electrical goods, automotive parts, home delivery wine merchants, etc.

WLN – What was your biggest investment to improve your business this year? What else have you done?

CSL has invested a lot of time and effort to develop a state-of-the-art data collation system that will provide detailed and accurate information not just for our benefit, but also to support communication and servicing of both existing and potential customers.

WLN – How are your existing products and services doing? Have you developed or upgraded your existing products and services recently?

At CSL, we are not limited to offering a standard range of modular conveyors, but can design and competitively engineer bespoke equipment most suited to meet individual handling applications. So by default, we are always adding to our product portfolio.

We have recently designed and manufactured a unique heavy duty conveyor for handling 1.5 ton pallets, which feed on to an automated vehicle loading system. At the other extreme, CSL has designed and supplied a customised lightweight slat conveyor with a special side grip elevator for handling small nasal spray containers.

We not only provide customers with handling solutions but provide many with servicing and maintenance programmes to ensure that equipment is properly maintained and working to maximum efficiency and safety, thus avoiding un-planned and costly downtime.

WLN – Have you launched any new products or services, and how are they performing?

The new CSL space saving spiral elevator offers an even smaller footprint and continues to create much interest as the unit is lighter in weight, but maintains the rigid structure and durability to support a high throughput of product, whilst also offering many new functional benefits.

The new narrow supporting column design improves visibility, whilst adding greater handling flexibility as the distance between the column and outer guide rail is increased and therefore, allows larger products to be handled.

Where floor space is restricted and a continuous flow of different shapes and sizes of products need to be conveyed between different floor levels, this provides an ideal solution.

CSL recently provided a customer with a solution for handling irregular shaped objectives, replacing an existing system that was not suitable to the task, with products from the new range of spiral and vertical elevators/lowerators.

WLN – What’s been your company’s single biggest achievement in business this year?

Against all the odds, CSL continue to experience controlled expansion. We are very proud of this achievement, which has been accomplished through long hours and dedicated teamwork.

On the back of previous successful installations, Toolbank – one of the UK’s leading distributor of hand and powered tools, has awarded Conveyor Systems Ltd (CSL) a third contract to provide an order picking, packing and sortation conveyor system for their new warehouse.

WLN – What was your favourite business moment in 2013?

Making a senior appointment to a company is an extremely difficult judgment that must be based on facts and also gut feeling. We all know that the consequences of a bad decision can be costly and this can be magnified many times in a company with a small team.

So on reflection, I believe that my decision to appoint Jim Farquhar as CSL’s sales manager must rank as one of my better decisions that I am very happy to say is now paying dividends in 2013.

WLN – Do you operate in any other countries besides the UK? How are you getting on there? Have you gone into any new territories recently?

No – Rather than stretching resources, we will continue to focus on servicing the needs of the UK materials handling/logistic sectors and stick to what we are good at.

WLN – Have you won any awards recently, or been accredited to any new standards?

Against fierce competition and some blue chip companies, CSL did achieve recognition as we progressed through to the finals of the PPMA Awards – having entered for two individual awards – ‘Exceptional Growth’ and ‘Customer Service Award’. Unfortunately there can only be one winner, but we take heart that we got so far with the help of testimonials from several of our customers.

WLN – Can you tell us about your major projects this year, and what they involved?

CSL has carried out work on several major projects including arvato who handle and distribute products for one of the world’s largest music companies. This is one of many projects completed on behalf of this customer on the same site in the last 14 years.

Also CSL was awarded a contract by a leading supply chain Management Company involved in the distribution of automotive parts within the UK. The design was to provide a conveying solution to support inbound stock replenishment and outbound order picking at its Distribution Centre.

The proposal was to switch operations from an existing platform / pallet goods lift, with the introduction of two spiral elevators that would speed up inbound stock replenishment and outbound order picking and dispatch handling, without the need for tote bins having to be palletised/ depalletised for the goods lift. The new CSL system looked to reduce both manual and truck handling activities, improve efficiency and accuracy of order picking.

CSL can also report excellent project success with leading food companies, a supermarket chain and e.commerce businesses, but as many will appreciate, they have a confidentiality clause that does not permit use of their names for promotional purposes.

However, we can report having installed the third phase of a major project at the UK’s leading bakery, taking product from post check weighers at the end of line, through to automated tray loading. This involved an extensive modular slat conveyor system – over 200m in length, along with eight spiral elevators. The total project was valued at almost £0.6M.

WLN – Can you tell us about your plans for 2014? Where do you see your business going?

WLN – Can you tell us about your plans for 2014? Where do you see your business going?

We have been very focused in our management and development of CSL and we look to build on our success and extend our customer base even further.

As reported, our order intake has been exceptional and we are looking to carry this on into 2014 and are looking forward to reporting a record year.

WLN – Are you looking at taking on more staff or expanding your premises next year?

As reported, we have already moved to new and larger premises and appointed a new Sales Manager, so there are no immediate plans to take on new staff. However, as our planned controlled growth continues at a pace – we may have to review this decision earlier than anticipated, as it is imperative that with expansion, we also maintain the high level of service to our existing customers.

WLN – Are you exhibiting at any major trade shows in 2014?

CSL has also committed to attending PPMA 2014 that will be held at the NEC – September 30th to October 2nd. Also, at the same time as completing this questionnaire, we have reserved a stand to attend IMHX 2016.

WLN – What other headline news from Conveyor Systems can our readers look forward to reading about in Warehouse & Logistics News next year?

We are looking forward to reporting that Conveyor Systems Ltd (CSL) has achieved its goals and its anticipations have been met with a record sales turnover for the whole year.

Phone: 01283 552255

Comments are closed.