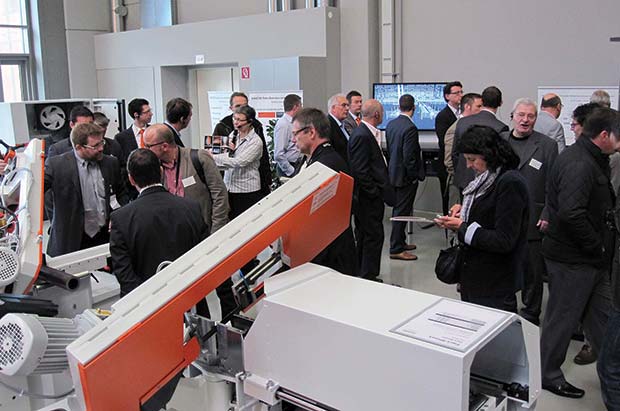

More than 600 trade visitors plus 152 journalists from across Europe, Russia, India, South Africa and the USA attended the FutureDays 2013 open house exhibition, held by KASTO at its factory and headquarters in Achern, southern Germany, from 14th to 17th May 2013. The company is renowned for the manufacture of metal sawing machines, which can be linked to various types of automated materials handling and storage systems for bar, other long stock, sheet, plate, and cut pieces.

The computer controlled storage systems are also produced as stand-alone products for stockholding and for feeding machine tools in factories, not only saws but also other types of machine such as lathes and laser profilers. The product range encompasses storage towers in compact, stand-alone design up to fully automatic honeycomb systems with thousands of storage cassettes. An increasing number of systems are being built with weather proof cladding for external installation, saving valuable space within factories and warehouses.

Highlighting the synergy between both sides of the business, KASTO’s sawing centres automate storage, handling, sawing, marking, palletising and bundling processes, including material identification, starting with the storage of the raw materials up to commissioning of the order. Machine shops and metal distribution centres have the security of receiving the turnkey installation from a single source.

KASTO is global market leader in terms of technology and units sold, having delivered over 140,000 saws and 1,450 storage systems worldwide. Its factories in Achern and Schalkau employ 600 people, 10 per cent of whom are apprentices. 90 engineers work in R&D and 5 per cent of sales is invested in new product development, particularly with the BRIC countries in mind.

Turnover in 2012 was 122.9 million euros, the third-best figure in the last ten years, while in the current fiscal year, global sales are so far holding up, despite weak demand in Europe. Around half of production is exported from Germany, including to the UK through the Milton Keynes-based daughter company. Subsidiaries are also located in the USA and France.

Now in its fifth generation of family ownership, the company was established in 1844 and has been run for the past 25 years by Armin Stolzer, who is now sole managing partner. The new management team comprising his daughter, Stephanie Baeumler (Marketing and Sales), Dieter Heyl (Production and Logistics) and Valentin Meier (design and procurement) was introduced to visitors, along with the new proprietors of the company group, comprising Mr Stolzer, his wife and both daughters, including their partners.

A key message at the show was the continuous optimisation of lean production, logistics and business practices throughout the factory, together with the adoption of a new shop floor management system and a move towards larger batch manufacture to reduce unit production costs.

Sawing machines on show ranged from the Workshop / Dealer range of bandsaws, circular saws and hack saws, which are now all made by KASTO, to a giant KASTOmaxcut AM 6×16 bandsaw for cutting aluminium blocks up to 2,200 mm wide by 800 mm high. The latter machine deployed a horizontal blade cutting horizontally to take slices off the top of the material to produce sheets, which were supported during sawing.

Other innovations included the latest evolution of the KASTOtec AM4 aluminium saw, capable of 1,200 m/min band speed and 800 mm/min infeed, and the KASTOtec AC 7 and 7×10 KPC bandsaws for use with carbide blades. There was an accent on aluminium cutting at the show, with plate and block saws (-plate and -cross) presented along with the -tec, -bbs and -maxcut machines.

On the storage system side of the business, FutureDays 2013 provided an opportunity to see the modular KASTOunitower C automated storage system for long stock, such as bar and tube. It is an entry-level tower store, joining its similarly named counterpart for accommodating sheet metal. The exhibition tower was connected directly to a saw, illustrating how manual handling can be eliminated. There was a total of seven storage and handling systems on show.

Aluminium was again a focus, with KASTOunitower, -portal, -top, -line and -compact systems promoted for storing long stock and/or sheet. Other handling highlights included a pedestal-mounted 6-axis robot for automated loading / unloading of a KASTOvariospeed circular saw, and a similar set-up where a robot performs deburring of cut pieces.

The latest developments from KASTO in the area of control technology; software including system simulation, virtual commissioning and value analysis; and human-machine interfaces for both sawing machines and warehousing were presented. KASTO has implemented over 300 systems worldwide that interface with customers’ computerised enterprise resource planning systems.

New, camera-based equipment for identification and measurement of cut pieces and other stock, various ‘green’ initiatives for reducing power consumption of KASTO products, and a new internet teleservice were all introduced by a succession of expert speakers from the company.

Another theme centred on applying automation to KASTO’s smaller saws through the addition of roller conveyors and measuring stops. Two classes of infeed and outfeed conveyors are offered, one for weights up to 450 kg/m and another of 3,000 kg/m capacity. Conveyor lengths are from 1,060 mm up to 2,130 mm and connections to all of KASTO’s saws are provided, with optional measuring systems for accurate cut piece length adjustment.

Sawing machine peripherals to promote safety, ease of use and cut piece quality were also promoted, such as multiple clamping devices and full bundle clamping systems. Minimum flow lubrication systems prevent coolant spillage when cutting tubes and profiles, which can now be performed efficiently with tungsten carbide tipped as well as bimetal blades. Further material flow and automation units on show included sheet handling options, buffer stations and material magazines for lights-out production.

KASTO Ltd

Ernst Wagner, Managing Director

Tel: 01908 571590

Email: sales@kasto.uk.com

Comments are closed.