Storage capacity and efficiency have been greatly improved at Doré Metal Services thanks to Atlet’s expertise and consultancy support. The specialist non-ferrous metal supplier selected Atlet Forte UFS four way reach trucks because they supported a new way of working with higher storage density and offered value for money. “Our decision was based on budgets, specification and capabilities and we chose to work with Atlet because they were committed to working with us and getting involved,” says Mike Lane, Managing Director of Doré Metal Services.

Storage capacity and efficiency have been greatly improved at Doré Metal Services thanks to Atlet’s expertise and consultancy support. The specialist non-ferrous metal supplier selected Atlet Forte UFS four way reach trucks because they supported a new way of working with higher storage density and offered value for money. “Our decision was based on budgets, specification and capabilities and we chose to work with Atlet because they were committed to working with us and getting involved,” says Mike Lane, Managing Director of Doré Metal Services.

Doré Metal Services is a privately owned company founded in 1969 that supplies the UK’s widest range of non-ferrous and special metal extrusions including aluminium, brass and stainless steel to distributors and engineering businesses throughout the UK. The company has built a reputation for being able to supply one of the most diverse ranges of aluminium extrusions in the UK, coupled with a next day national delivery service. The business has been growing steadily in recent years and warehousing was spread across a number of sites in old fashioned buildings. The company recognised that this was inefficient and decided to consolidate its operations into a new 3,000 sq metre (32,000 sq ft) distribution warehouse at Sittingbourne.

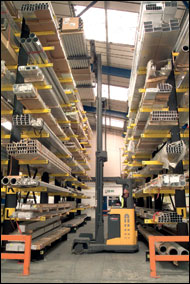

The new building presented the ideal opportunity to optimise handling and storage processes. The company had been using a variety of racking types in its existing buildings and wanted to configure the new warehouse with a combination of cantilever and “A” frame racking that offered a flexible and efficient way of storing extrusions, tubes, bars and billets up to six metres in length. Handling had been undertaken by conventional counterbalance trucks in the previous operation.

Doré recognised that this would not be practical in the new warehouse because of the racking density and aisle widths required to achieve the maximum storage capacity. A number of potential lift trucks suppliers, including Atlet, were ask to provide proposals based on overall requirement.

“We had a good idea of what we wanted to do and the choice came down to side loader or four way reach trucks,” says Mike Lane. “We soon realised a side loader didn’t have the flexibility we needed but the four way reach truck was able to do everything we needed.”

Atlet proposed its Forte UFS four way reach truck that can be driven forwards, backwards and sideways because all three wheels can swivel. This makes it exceptionally manoeuvrable in a confined warehouse environment and ideal for handling long loads in different types of racking. During the selection process Doré Metal Services had identified that a side loader truck would not offer the flexibility or performance required to support its busy operations. The company was making a six-figure investment in the racking alone and wanted to make sure it got the best possible performance.

Atlet recognised that its proposals represented a radical change for Doré and brought in a project manager to advise and consult on the overall design of the warehouse. This included the configuration of the racking and the aisle widths to ensure the maximum storage capacity and efficiency from the available cube space.

“Aisle widths are critical because we wanted to get more in the warehouse but with flexibility and potential for future growth,” says Mike Lane. “This was a sizeable investment and we needed to maximise what we do safely.”

Doré’s original plan had been to have a series on aisles running along the whole length of the building. However Atlet suggested the inclusion of a transit aisle running across the middle of the warehouse as this would reduce the average distance the truck would move to complete each handling task. The aisle reduced overall storage capacity but this was more than offset by improvements in efficiency and productivity. Ultimately the transit aisle also formed a convenient boundary between the cantilever racking at one end of the warehouse and the “A” frame racking at the other.

“One of the things we liked about Atlet was the potential for aftercare,” says Mike Lane. “The consultative aspects were extremely beneficial and more than we expected.”

The warehouse operates on a single day shift to support next day delivery to customers throughout the UK using carrier services and the Doré’s own vehicles. It offers a same-day service to customers in the South East. Operations have to be productive and efficient and picking is often completed on-demand and just-in-time to fulfil orders received throughout the day.

One of the key decisions when configuring the warehouse was whether one truck could meet the overall requirement. The business relies on the ability to pick orders quickly and the company decided to purchase a second truck after assessing factors such as overall performance, battery recharge periods and the potential disruption to operations caused by unexpected truck downtime.

“We need to pick quickly, often within an hour to support the business requirement for rapid customer fulfilment,” says Mike Lane. “This is why we went for the second truck.”

The result of the changes and the investment made by Doré Metal Services has been impressive. The company has grown by more than 28 per cent since the move to the new warehouse, based on top and bottom line figures. Around two thirds of the business involves supplying other stockists with highly diverse products. The remaining third comes from direct sales to customers such as engineers and OEMs who require speciality non-ferrous extrusions.

This growth has been achieved by increasing overall efficiency without adding to the number of different lines stocked. Throughput has been improved and the overall stock weight is around 15 per cent higher than before thanks to the increased storage capacity on the new site.

The warehouse was commissioned to extremely tight deadlines, which meant the new trucks were not available when it opened. Atlet loaned two trucks for a fortnight until the new equipment was ready for delivery. It also arranged for all of the drivers to be trained to use what for them was a completely new type of truck. In addition to the different type of truck the warehouse is itself much higher than before at 7.5 metres to the top racking beam and drivers needed to be comfortable with the new operation.

“These are new methods of operation but the feedback has been very positive,” says Mike Lane. “The trucks have been reliable and we are very pleased with them.”

Atlet Limited

Paul Forster

Tel: 01844 215501

www.atlet.co.uk

Comments are closed.